Popular in your industry

Related Searches:

Top categories

About spinach cut machine

A spinach cutter machine is a specialized device used for cutting and chopping spinach leaves or other leafy greens. Its main purpose is to streamline the food preparation process by quickly and efficiently cutting large quantities of spinach into smaller, more manageable pieces. This machine is widely used in commercial kitchens, restaurants, and food processing facilities, where a large volume of spinach needs to be processed regularly. Its design typically includes sharp blades or cutters that are specifically configured to cut leafy greens with precision, ensuring uniformity in the size of the cut pieces. Additionally, these machines often come with features that allow for customization of the cutting size, making them versatile for various culinary applications.

Types of spinach cutter machines

The most common types of palak cutter machines are the bowl-type cutter and the continuous belt cutter. The bowl-type cutter, also known as a batch cutter, is designed to handle a specific volume of spinach at a time. Operators load the spinach into a bowl or container, and the machine processes the entire batch, cutting the leaves as per the configured specifications. This type is suitable for smaller to medium-scale operations where batch processing is sufficient. On the other hand, the continuous belt cutter, as the name suggests, operates continuously, allowing a constant flow of spinach to be cut. In this type, spinach leaves are fed onto a conveyor belt, where they pass through cutting mechanisms that slice them into the desired sizes. Continuous belt cutters are ideal for high-volume production environments, such as large food processing facilities, where a consistent and uninterrupted cutting process is essential to meet demand.

Materials of the spinach cutter machine

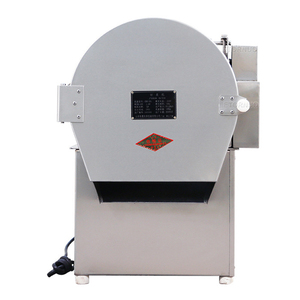

The spinach chopper machine is usually made of stainless steel, which is known for its durability, resistance to corrosion, and ease of cleaning. The use of stainless steel in the construction of these machines ensures that they can withstand the rigors of a commercial kitchen or food processing setting. Furthermore, the material also prevents the risk of corrosion from exposure to acidic components in foods like spinach. This feature is particularly crucial for maintaining food safety standards. The robustness of stainless steel makes the spinach cutter machine a long-lasting piece of equipment that can efficiently handle the demands of regular use in professional settings. Moreover, some models may incorporate food-grade plastic components in areas that do not come into direct contact with the spinach, adding a level of customization to meet specific needs in terms of durability and maintenance.

How to use a spinach cutter machine?

First, operators should ensure that the spinach cutter machine for home is set up on a stable and flat surface. The next step is to wash the spinach leaves thoroughly, removing any debris or impurities. Following this, the leaves should be dried to prevent excess moisture, as this can affect the cutting process. Depending on the type of machine, users need to familiarize themselves with the specific operation and safety instructions provided by the manufacturer. Then, they can proceed to feed the spinach leaves into the machine, ensuring they are within the capacity limits. Once the machine is in operation, users can adjust the settings to achieve the desired size of the cut. It is important to keep hands and any other items away from the cutting mechanisms during operation to prevent accidents. After the cutting process is complete, users can collect the cut spinach for immediate use or storage.