Introduction to Wood Beveling Machines

Wood beveling machines are specialized tools designed for creating precise bevels and chamfers on various woodwork pieces. These machines are indispensable in woodworking shops, facilitating smooth and accurate cuts that are essential for joints, edges, and decorative finishes.

Types and Applications

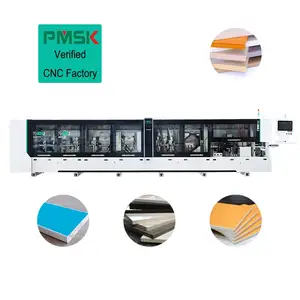

The woodworking beveling equipment category encompasses a variety of machines, each tailored for specific beveling tasks. Users will find equipment ranging from handheld bevelers for on-site adjustments to industrial-grade machines for high-volume production. These machines are utilized in crafting furniture, cabinetry, and in architectural millwork where precision beveling is crucial.

Features and Materials

A wood edge beveling machine is designed with features to handle different wood densities and grains. Typically constructed from durable metals, these machines boast robust cutting blades, adjustable angles, and variable speed controls to accommodate the intricacies of wood beveling. The materials used ensure longevity and consistent performance under repetitive use.

Advantages of Modern Beveling Machines

Modern wood beveling tools offer significant advantages, such as enhanced precision with digital angle readouts and improved safety features. The efficiency of these machines translates into smoother production flows and better-quality finishes, making them a valuable asset in any woodworking operation.

Choosing the Right Machine

Selecting the appropriate woodworking beveling machine requires understanding the specific needs of your project or production line. Factors to consider include the machine's beveling capacity, the type of wood being worked on, and the desired speed of operation. It's essential to compare the features of different machines to find the one that aligns with your woodworking requirements.

Maintenance and Safety

Maintaining a wood beveling machine involves regular cleaning and part inspections to ensure optimal functionality. Safety is paramount; thus, operators should be well-trained in machine use and adhere to safety guidelines to prevent accidents during operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4