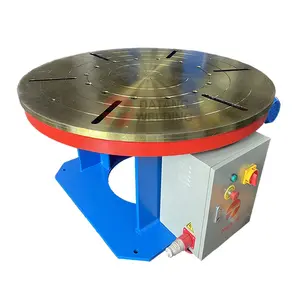

Exploring the Versatility of Welding Rotary Tables

Welding rotary tables are pivotal in enhancing the precision and efficiency of welding operations. These tables facilitate the positioning of workpieces, allowing for seamless access to the areas requiring welding. By enabling rotation and angling of the material, welders can achieve high-quality joins without the need to manually reposition heavy components, thereby increasing safety and productivity in the workshop.

Types and Applications of Rotary Welding Positioners

The variety of rotary welding positioners caters to diverse welding requirements. From tig welding rotary tables designed for delicate, precise welding tasks to robust 360 welding cutting rotary turn tables, the applications are extensive. These positioners are commonly utilized in automotive, manufacturing, and metalworking industries, where precision and efficiency are paramount. The rotary positioner table is particularly beneficial for tasks that require continuous welding, allowing for a uniform and consistent weld bead.

Features and Materials of Rotary Welding Positioners

A rotary welding positioner turntable is engineered to accommodate various weights and sizes of metal pieces. Constructed from durable materials, these tables can withstand the rigors of welding operations while ensuring stability and support. Features such as adjustable height and tilt range enhance the functionality, allowing welders to set the optimal position for each task. The rotating mechanism of a rotary welding positioner diy setup can be customized to suit specific welding processes, providing flexibility for those creating a homemade rotary welding table.

Advantages of Using a Welding Rotary Table

The use of a welding rotary table brings numerous advantages to the welding process. It significantly reduces the time and effort required to weld complex pieces by providing easy access to all sides of the workpiece. This accessibility not only improves the quality of the welds but also minimizes the physical strain on welders, leading to a safer and more comfortable working environment. Additionally, the precision afforded by a rotary welding positioner turntable table ensures that each weld is consistent, which is crucial for maintaining the integrity of the final product.

Choosing the Right Welding Rotary Table for Your Needs

Selecting the appropriate welding turn table involves considering the specific requirements of your welding projects. Factors such as the maximum weight capacity, table dimensions, and rotational speed should align with the types of materials and the nature of the work being performed. For those seeking a customized solution, a diy rotary welding table or a diy rotating welding table can be tailored to unique specifications, providing a cost-effective alternative to off-the-shelf models.

Integrating Rotary Tables into Your Welding Setup

Incorporating a vevor welding positioner or a vevor rotary welding positioner into your welding setup can transform your operations. These positioners complement other welding accessories, creating a comprehensive system that caters to a wide range of welding tasks. Whether you are looking to enhance a commercial production line or upgrade a training facility, the right welding rotary table can make a significant impact on the quality and efficiency of your welding projects.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4