Exploring the Versatility of Water Tap Moulds

The water tap mould is an essential component in the manufacturing of water taps, playing a pivotal role in shaping the functionality and aesthetics of this common plumbing fixture. These moulds are crafted to meet the diverse needs of businesses, ensuring that each tap meets industry standards and consumer expectations.

Types and Applications

There are various types of moulds available, each designed for specific tap models and functionalities. From single-lever mixer moulds to those for creating sophisticated sensor taps, the range is extensive. The application of these moulds spans across residential, commercial, and industrial sectors, highlighting their importance in everyday water supply systems.

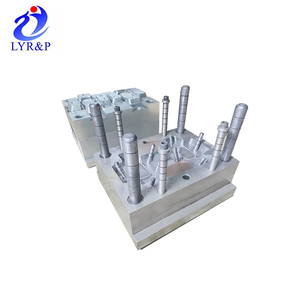

Material Insights and Features

Materials used in water tap mould production include iron, aluminum, and steel, each selected for its durability and resistance to wear. The intricacies of mould design are critical, as they must ensure precise water flow and handle mechanisms. Features such as anti-corrosion properties and thermal resistance are also integral to the longevity and performance of the moulds.

Advantages of Precision Moulding

Precision in moulding ensures that water taps function reliably, preventing leaks and maintaining water efficiency. The adaptability of moulds to create various designs allows for innovation in tap styles, meeting both functional and decorative needs. Furthermore, the standardization of certain mould components can lead to cost reductions in mass production.

Selection Considerations

When selecting a water tap mould, it is crucial to consider the compatibility with the intended production material and the design complexity. Suppliers on Alibaba.com offer a breadth of options, catering to customized and standard designs. It is advisable to engage with suppliers to ensure the mould meets the specific requirements of the intended tap design.

Integration with Manufacturing Processes

The integration of a water tap mould into production lines is a streamlined process, with the mould's design facilitating easy installation and removal. This efficiency is beneficial for businesses looking to optimize their manufacturing processes and maintain productivity.

Incorporating a water tap mould into your production line can significantly influence the quality and appeal of your water tap offerings. Alibaba.com serves as a gateway to connect with experienced suppliers who can provide moulds that align with your production goals and standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4