Introduction to Used Injection Moulding Machines

The realm of manufacturing is diverse, and within it, used injection moulding machines play a pivotal role in the production of plastic components. These machines are integral to various industries, offering a sustainable option for businesses looking to optimize costs without compromising on productivity. A used injection machine is not merely a cost-effective alternative but also a step towards resourcefulness in a competitive market.

Types and Applications

Different types of used molding machines cater to a broad spectrum of applications. From creating simple household items to complex automotive components, these machines are versatile. The second hand plastic injection machine is particularly sought after for its applicability in producing packaging materials, electronic casings, and medical devices. Each machine's adaptability to specific tasks makes it a valuable asset in the production line.

Features and Materials

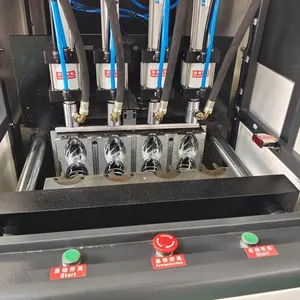

The construction of a used plastic molding machine involves robust materials that withstand rigorous use. Features such as advanced servo-valve systems and specialized screws enhance the plasticizing capacity, ensuring efficient production cycles. The clamping force of these machines, which can vary significantly, is designed to resist external forces during the molding process, thus maintaining the integrity of the molded products.

Advantages of Modern Used Equipment

Opting for used injection molding equipment does not mean compromising on the technological front. Many second-hand machines come equipped with modern features that promote precision and speed, akin to their newer counterparts. The advantage lies in the reduced investment cost, allowing businesses to allocate funds to other critical areas like research and development or quality control.

Ensuring Quality and Durability

Quality and durability are paramount when selecting a used injection moulding machine. Machines that have undergone constant design improvements and feature enhancements such as new steel bush structures in the clamping unit, promise minimized wear and reduced lubrication costs. These improvements are crucial for businesses focusing on long-term operational efficiency.

Choosing the Right Machine

When it comes to expanding production capabilities, a second hand injection moulding machine can be the right choice. It is essential to consider the specific requirements of your applications, such as the size of preforms and the type of plastic materials to be molded. A used vertical injection moulding machine might be ideal for certain specialized tasks, offering the exact clamping force needed for precision work.

In conclusion, a used plastic injection molding machine represents a strategic investment for businesses aiming to enhance their production capabilities. With a focus on sustainability and cost-efficiency, these machines continue to be a mainstay in the manufacturing sector.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4