Exploring the Versatility of Ultrasonic Welders

Ultrasonic welders stand at the forefront of innovative joining technologies, offering a sophisticated method for fusing materials with precision and efficiency. These devices harness high-frequency ultrasonic acoustic vibrations to create solid-state welds, eliminating the need for adhesives, screws, or other traditional binding methods. The process of ultrasonic welding plastic is not only highly effective but also environmentally friendly, as it reduces waste and energy consumption.

The Mechanics of Ultrasonic Welding

At the core of an ultrasonic welder is the ultrasonic welding horn, a critical component that delivers vibrational energy to the materials being joined. This energy causes the material to heat and plasticize, forming a robust bond upon cooling. The versatility of ultrasonic welding is evident in its ability to join dissimilar materials, making it a valuable tool for applications in automotive, medical, and consumer electronics industries.

Applications Across Industries

The application of ultrasonic welding extends beyond plastic, with ultrasonic metal welding gaining traction for its clean and strong joints. Industries benefit from the technology's ability to weld thin sheets and wires, as seen in the electrical and automotive sectors. Furthermore, the advent of ultrasonic welding fabric has revolutionized the textile industry, enabling seamless joining of fabrics without compromising their integrity.

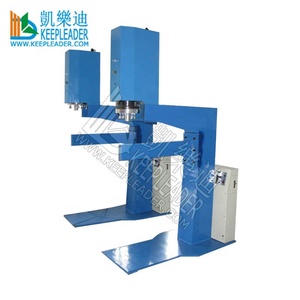

Types of Ultrasonic Welders

The Alibaba platform showcases a variety of ultrasonic welders to meet diverse industry needs. From handheld ultrasonic welder units that offer portability and convenience, to heavy-duty branson ultrasonic welder systems designed for intensive operations, buyers can find the right tool for their specific requirements. Specialized devices like ultrasonic spot welder and spin welders cater to niche applications, providing targeted solutions for unique welding challenges.

Choosing the Right Ultrasonic Welder

Selecting an ultrasonic welder involves considering the material compatibility, weld strength requirements, and the specific application. For intricate tasks, a branson 2000 ultrasonic welder or a telsonic ultrasonic welder might be suitable, known for their precision and control. For those needing to join larger areas, plastic vibration welding equipment offers an effective solution. It's essential to review the specifications provided on Alibaba.com to ensure the chosen welder meets the project's demands.

Advancements in Ultrasonic Welding Technology

Innovation continues to drive the ultrasonic welding industry forward, with improvements in ultra welding techniques and equipment. The development of more sophisticated control systems and welding horns has enhanced the capabilities of ultrasonic welders, allowing for more complex and delicate welding tasks to be accomplished with greater accuracy and repeatability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4