Introduction to Tube Scarfing Inserts

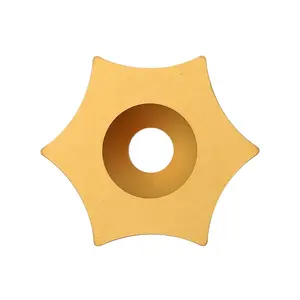

Tube scarfing inserts are specialized components used in the metal fabrication industry to remove weld beads from tubes. These precision tools are essential for ensuring a smooth finish on the inside surface of welded tubes, which is critical in applications where material flow and cleanliness are paramount.

Types and Applications

OD scarfing inserts and their counterparts are designed for various applications, ranging from heavy-duty industrial use to precision tasks. They are employed in industries such as automotive, aerospace, and construction, where the integrity of the tube's interior surface is crucial. The versatility of these inserts allows them to be used on a multitude of materials, including steel, aluminum, and copper.

Features and Materials

The materials used in the manufacture of tube scarfing inserts include durable metals such as tungsten carbide and high-speed steel. These materials are selected for their resistance to wear and their ability to maintain sharpness over prolonged periods. The design features of these inserts, such as their cutting angles and profiles, are meticulously crafted to ensure efficient removal of weld beads without compromising the tube's structural integrity.

Advantages of Using Quality Inserts

Utilizing well-crafted tube scarfing inserts in the scarfing process offers numerous advantages. They provide a consistent finish, which is essential for maintaining the quality of the tubes. Moreover, the durability of these inserts means less frequent replacement, leading to reduced downtime and increased productivity in manufacturing settings.

Eco-Friendly and Comfort Considerations

In addition to their functional benefits, modern tube scarfing inserts are designed with environmental considerations in mind. Manufacturers are increasingly focusing on producing eco-friendly options that minimize waste. The comfort of the operator is also taken into account, with ergonomic designs that reduce fatigue during the scarfing process.

Customization and Sustainability

For businesses with specific needs, there is the possibility of customizing the tube scarfing inserts to suit particular applications or tube sizes. This customization ensures that the inserts can perfectly match the requirements of the task at hand. Furthermore, the focus on sustainability in the production of these inserts aligns with the growing demand for environmentally responsible manufacturing practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4