Introduction to TNMG Ceramic Inserts

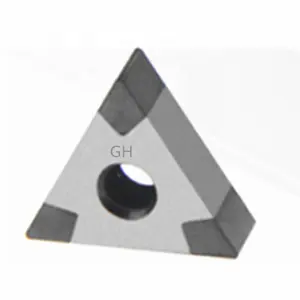

TNMG ceramic inserts are precision cutting tools used extensively in metalworking for shaping, cutting, and finishing metals and other materials. These inserts are crafted from durable ceramic materials, which allow them to maintain hardness at elevated temperatures and ensure longevity in high-speed cutting applications.

Types and Applications

The variety of tnmg ceramic inserts caters to a broad spectrum of turning operations. Each insert is designed to meet specific requirements, from general-purpose machining to finishing tasks. The utility of these inserts spans across industries, including automotive, aerospace, and manufacturing, where precision metalworking is crucial.

Features and Materials

Ceramic turning inserts are known for their impressive heat resistance and wear life compared to their carbide counterparts. The material composition of tnmg inserts includes alumina, silicon nitride, and other advanced ceramics, offering enhanced toughness and thermal properties.

Advantages of TNMG Ceramic Inserts

The use of tnmg ceramic inserts in lathes brings several advantages. Their ability to withstand high temperatures allows for faster machining speeds, which in turn increases productivity. Additionally, the robustness of ceramic reduces the frequency of tool changes, enhancing operational efficiency.

Selection Considerations

When selecting a tnmg insert, it is essential to consider the material being machined and the type of turning operation. The geometry and grade of the insert play a pivotal role in achieving the desired surface finish and dimensional accuracy.

Optimizing Your Machining Process

Incorporating the right tnmg ceramic insert into your machining process can significantly optimize performance. With a variety of geometries and ceramic grades available, these inserts are adaptable to a wide range of turning applications, ensuring precise and efficient material removal.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4