Introduction to Textile Shredding Machines

Textile shredding machines are essential equipment in the recycling and waste management industry. These machines are designed to efficiently break down various textile materials into smaller fragments, facilitating the recycling process and contributing to sustainable practices. The versatility of textile waste shredding equipment allows for processing a wide range of materials, from clothing to industrial textiles.

Types and Applications

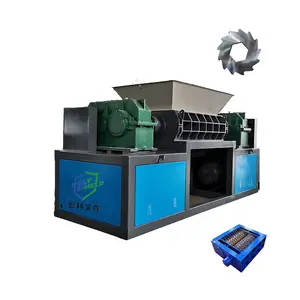

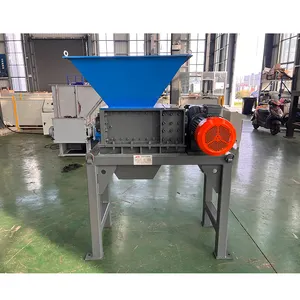

There are several types of textile shredders available, each suited for specific applications. Single-shaft shredders are commonly used for their efficiency in processing homogeneous materials, while dual-shaft shredders are preferred for their ability to handle a mixture of textiles with varying densities and compositions. The end product of these machines can be used for insulation materials, carpet padding, or as a raw material for producing new textile products.

Features and Materials

Modern textile shredding machines are constructed using robust materials that withstand the demanding environment of textile processing. Components are typically made from hardened metals, capable of enduring the stress of shredding tough materials. Features may include customizable screens for size specificity, reversible functionality to clear jams, and energy-efficient designs that reduce operational costs.

Advantages of Advanced Shredding Technology

The latest advancements in textile shredding technology offer numerous benefits. Enhanced cutting mechanisms provide consistent shredding, which is crucial for downstream processing. Energy efficiency is another significant advantage, as it not only lowers expenses but also aligns with eco-friendly objectives. Safety features are integral to these machines, ensuring that operation risks are minimized.

Innovations in Textile Shredding

Innovation in the field of industrial textile shredding has led to the development of machines that are not only more efficient but also more user-friendly. Automated feeding systems, noise reduction technologies, and diagnostic software are some of the advancements that have transformed textile shredding machines into sophisticated recycling solutions.

Choosing the Right Machine

Selecting the appropriate textile shredding machine is crucial for achieving desired outcomes. Factors to consider include the type of textile material, the required size of the shredded output, and the volume of material to be processed. It is important to assess the machine's capacity, maintenance requirements, and compatibility with existing recycling operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4