The moniker swing machine refers to a contemporary evolution of the classic sewing machine, tailored to satisfy the varied demands of the modern textile and apparel sectors. These devices range from simple, domestic-use models to sophisticated systems engineered for industrial purposes. They are indispensable in crafting an array of items, from everyday clothing to elaborate haute couture creations.

Types and Features of Swing Machines

Exploring the array of swing machines reveals a gamut of models, each with distinctive attributes. The mini swing machine is diminutive and often mobile, perfect for minor repairs or petite projects. In contrast, the industrial swing machine is a behemoth, tailored for bulk manufacturing with attributes such as swift stitching and robust construction. Specialty devices like the embroidery sewing machine are capable of detailed patterns, a testament to their sophisticated programming. The hand swing machine continues to be esteemed for its straightforward operation, commonly chosen by novices or for instructional use. Each variant serves different purposes, from the singer swing machine with its intuitive interface to the brother swing machine, lauded for its cutting-edge technological features.

Swing Machine Structure and Core Components

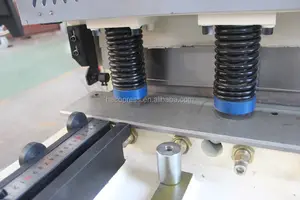

A swing machine's architecture is intricate, composed of a complex network of components. Central to its operation is the swing machine motor, which propels the needle's action. This motor's force is conveyed through a series of gears, fine-tuned for exactitude. The swing machine needle is merely the visible part; underneath, a bobbin and shuttle collaborate to produce stitches. Premium models may incorporate touchscreens and sensors that enable a fluid sewing experience, permitting on-the-go adjustments to stitch size, tension, and pattern choices.

Materials and Durability

The construction of swing machines involves materials selected for their endurance and efficacy. Metals like stainless steel and aluminum alloy are prevalent in the framework and inner workings due to their durability and corrosion resistance. Plastic parts are typically advanced composites, chosen for their lightness and malleability. The material selection directly influences the swing machine cost and its lifespan. For example, a leather swing machine might incorporate specialized needles and more potent motors to penetrate tough materials, thereby warranting a higher price of swing machine.

Business Usages and Applications

In various commercial environments, swing machines are fundamental. Tailor shops often rely on a juki swing machine as their cornerstone, facilitating the production of diverse apparel. Advertising firms may employ swing machines to fabricate promotional banners and flags. The construction sector might deploy heavy-duty machines for stitching robust materials for equipment or protective gear. Each use case not only necessitates a particular swing machine type but also significantly contributes to business value by boosting productivity and enabling the creation of a broad product range.

Functions and Capabilities

Swing machines are engineered to execute tasks from elementary stitching to elaborate embroidery. Capabilities encompass straight stitching, zigzagging, buttonholing, and ornamental stitching. Sophisticated machines boast programmable patterns, automatic thread trimming, and even Wi-Fi connectivity for pattern downloads. The industrial swing machine typically offers rapid stitching speeds and enlarged tables for expansive projects, whereas a mini swing machine may prioritize user-friendliness and straightforwardness.

Distinctive Features and Selling Points

The distinctive selling propositions of swing machines often reside in their features. A singer swing machine may be celebrated for its extensive stitch repertoire, while a brother swing machine could highlight smart device connectivity for importing designs. The jack swing machine is recognized for its energy-efficient motor, and a leather swing machine might be equipped with specialized presser feet for managing thicker fabrics. These characteristics distinguish them in a competitive marketplace, catering to both amateur stitchers and seasoned tailors.

Benefits and Problem-Solving

The advantages of swing machines are numerous. For enterprises, the modern machine's speed and efficiency translate into heightened productivity. For individual users, conveniences such as automatic threading and cutting can demystify the sewing process, enhancing accessibility. The precision offered by a computerized swing machine is essential for businesses where stitch quality can be a distinguishing feature.

How to Use and Operate Effectively

Effective operation of a swing machine necessitates a grasp of its functions and settings. For novices, beginning with a mini swing machine may be less intimidating, while professionals might opt for the adaptability of a computerized swing machine. It is crucial to diligently peruse the manual, practice threading, and commence with straightforward projects to cultivate confidence and proficiency.

How to Choose the Right Swing Machine?

Selecting the appropriate swing machine involves evaluating your requirements. A hand swing machine may suffice for sporadic use, whereas an industrial swing machine is essential for high-volume tasks. Consider the fabric types you will handle, the machine's stitching options, and any supplementary features that might enhance your specific endeavors.

How to Clean and Maintain

Ensuring the longevity of your swing machine is contingent upon regular maintenance. Routine dusting, lubricating moving parts, and replacing needles when they dull are all integral to upkeep. For an industrial swing machine, arranging professional maintenance checks can avert expensive operational interruptions.

How to Install and Get Started

Setting up a swing machine typically entails positioning the device stably, installing the needle and bobbin, and threading the machine as per the manufacturer's guidelines. For more complex models, professional setup might be advisable to guarantee all functionalities are correctly configured.

Target Audience and Meeting Needs

The intended market for swing machines is as diverse as the machines themselves. A singer swing machine may target domestic sewers seeking dependability and simplicity, while a jack swing machine could appeal to businesses in need of speed and efficiency. Discerning the preferences and requirements of the intended demographic is crucial in choosing the most suitable machine.

What is the lifespan of a swing machine?

The service life of a swing machine can vary widely, contingent on its use and upkeep. Industrial models, designed for enduring high volumes, can last for extended periods with appropriate care. Regular servicing and prompt repairs are vital in prolonging the lifespan of any swing machine, be it a sturdy kenmore swing machine or a versatile usha swing machine.

Can swing machines handle all types of fabrics?

Although swing machines are remarkably versatile, not every model is suitable for all fabric types. Lighter machines are optimal for delicate fabrics like silks and cottons, while a leather swing machine is expressly crafted to manage heavier, more resilient materials. It is advisable to seek guidance from the manufacturer or a well-informed swing machine shop near me to ensure the selection of a machine that aligns with your fabric needs.

Are there swing machines suitable for both home and commercial use?

Indeed, there are swing machines that straddle the line between domestic and commercial utility. Brands such as singer and brother provide versatile machines that can accommodate the occasional home project while possessing the robustness needed for small-scale business operations. The decision should balance the swing machine cost against the features and durability on offer to ensure it fulfills both home and commercial requirements effectively.

Identifying the ideal swing machine for your enterprise on Alibaba.com can be a strategic decision that fosters increased productivity and expansion. With an extensive selection available, from the compact mini swing machine to the formidable industrial swing machine, there is a solution tailored to every business necessity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4