Understanding Staple Making Machines

Selecting the right staple making machine is crucial for the efficiency and productivity of your workshop. These machines are designed to manufacture staples, which are essential fasteners in various industries. From packaging to construction, staples are integral in binding materials together. A staple making machine must be chosen with precision, ensuring it aligns with your production needs and space constraints.

Types and Applications

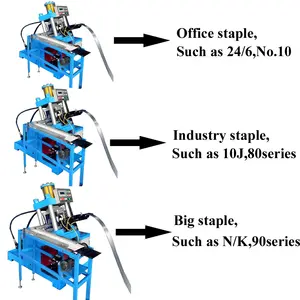

The types of staple making machines vary, each suited to different production volumes and staple sizes. Some are tailored for heavy-duty industrial use, while others are more appropriate for smaller, craft-based applications. The application of these machines spans across furniture manufacturing, where staples are used for upholstery, to office supplies, where they secure documents.

Features and Materials

A staple making machine comes with a range of features designed to enhance usability and efficiency. These include user-friendly interfaces, adjustable speed settings, and durability for continuous operation. The materials used in the construction of these machines are typically high-grade metals, ensuring longevity and resistance to wear and tear.

Advantages of Modern Machines

Modern staple making machines offer numerous advantages, such as energy efficiency, which can reduce operational costs. They also boast improved safety features, minimizing the risk of accidents during operation. Additionally, the precision engineering of these machines ensures consistent staple quality and size, which is crucial for meeting industry standards.

Production Capacity Considerations

When investing in a staple making machine, it's important to consider its production capacity. This not only affects the volume of staples you can produce but also impacts your ability to meet market demands. Machines with higher production capacities can offer greater throughput, which is essential for larger operations.

Operational Requirements

The operational requirements of a staple making machine include ease of maintenance, skill level needed for operation, and the cost of repairs. It's important to select a machine that is user-friendly and doesn't require extensive training to operate, ensuring smooth production processes.

For a diverse selection of staple making machines, Alibaba.com offers a platform where various suppliers showcase their machinery. With an easy-to-use search function, you can find the machine that meets your production requirements and connect with suppliers to fulfill your business needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4