Introduction to Spring Wire Straighteners

Spring wire straighteners are essential tools in the realm of manufacturing, designed to straighten metal wire that is used in various industrial applications. These devices are crucial for operations that require precise manipulation of wire to ensure the end product meets stringent specifications. The straighteners come in various models, each tailored to accommodate different wire diameters and materials, ensuring a broad range of functionality.

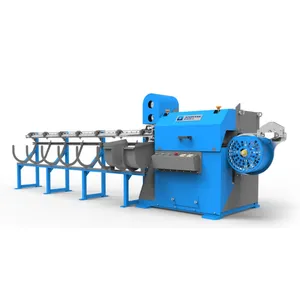

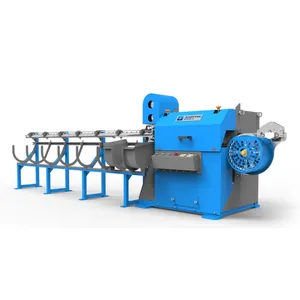

Types and Applications

The diversity of spring wire straighteners reflects the variety of their applications. From heavy-duty models capable of handling large volumes of metal to more delicate machines suitable for finer wires, each type serves a specific purpose. These straighteners are employed in the automotive, aeronautics, and consumer electronics industries, among others, where the integrity of wire forms is paramount.

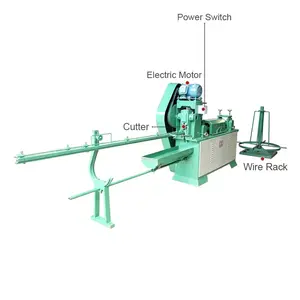

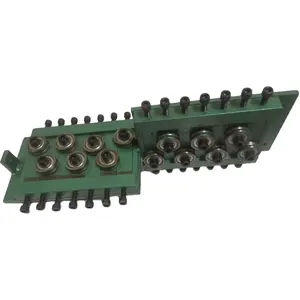

Features and Materials

A spring wire straightener is typically constructed from durable materials capable of withstanding the rigors of continuous operation. Features may include adjustable rollers, tension control, and user-friendly interfaces, which contribute to the machine's efficiency and ease of use. The materials used in manufacturing these straighteners are selected for their strength and resistance to wear, ensuring longevity and consistent performance.

Advantages of Using a Wire Straightener

Utilizing a wire straightening machine in the manufacturing process offers numerous advantages. It enhances precision, increases production speed, and reduces material wastage. Moreover, the consistency provided by a wire straightener is invaluable in maintaining the quality of the end product, which is crucial for manufacturers aiming to uphold high standards.

Choosing the Right Straightener

Selecting the appropriate wire straightening tool is a decision that should be made after careful consideration of the manufacturing needs. Factors such as wire size, material type, and the scale of production should guide the selection process. Alibaba.com hosts a variety of vendors, each offering a range of straighteners to suit different industrial requirements.

Considerations Before Purchase

Before procuring a spring wire straightening device, it is important to conduct thorough research to identify a machine that aligns with your operational demands. Prospective buyers should consider the machine's compatibility with their current manufacturing processes and the potential for scalability. It is advisable to review the specifications and features of each model to ensure the chosen straightener will deliver the desired outcome.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4