Explore the Versatility of Spot UV Coating Machines

Spot UV coating machines are integral components in modern printing and finishing processes, offering a specialized application of UV coating to printed materials. This technique enhances visual appeal by adding shine and texture to specific areas of a product. The UV varnishing machine is designed to cater to a variety of materials, ensuring that each application is precise and consistent.

Types and Applications of Spot UV Coating

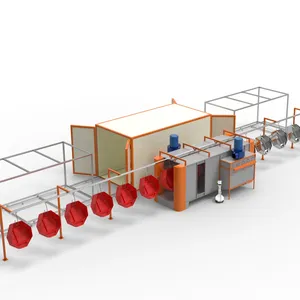

The range of spot UV varnish machines includes options from manual to fully automated systems. These machines are adept at handling tasks from simple spot varnishing to complex patterns on a plethora of substrates. Common applications include business cards, book covers, and packaging materials, where the spot UV technique provides a tactile and visual enhancement that distinguishes products in the marketplace.

Features and Materials Compatibility

A UV spot coater is engineered to work with a variety of inks and substrates, including paper, plastic, and metal. Key features often include an advanced curing system that ensures quick drying, high-efficiency energy usage, and a user-friendly interface. The compatibility with diverse materials allows for a broad spectrum of applications, from decorative finishes on personal items to functional coatings on industrial products.

Advantages of Using Spot UV Coating Equipment

Utilizing a spot UV coating machine offers numerous advantages, such as enhanced product durability and an improved aesthetic finish. The application of UV coating can also provide additional protection to the underlying material, making it more resistant to wear and tear. Moreover, the precision of spot application ensures that the coating is only applied where needed, reducing waste and increasing efficiency.

Environmental Considerations and Efficiency

Environmental responsibility is a significant consideration for businesses today. Spot UV coating machines are designed with this in mind, often featuring systems that minimize volatile organic compound (VOC) emissions. Additionally, the high powder recovery rate of these machines demonstrates their efficiency, making them a conscientious choice for businesses looking to reduce their environmental footprint while maintaining productivity.

Choosing the Right Spot UV Coating Machine

Selecting the appropriate UV coating machine for your business involves considering the specific requirements of your projects. Factors such as the size of the workpiece, the desired throughput, and the level of automation required should guide your decision. With a range of machines available, from those suitable for small-scale operations to high-volume production lines, there is a spot UV coating solution to meet the needs of any business.

![[JT-SGJ620]Micro Spot UV Varnish Coating Machine Fully Automatic Spot UV Coating Machine](https://s.alicdn.com/@sc04/kf/H030f2d07b93447e2bfb309f4dd4af79bO.jpg_300x300.jpg)

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4