Introduction to Spinning Simplex Machines

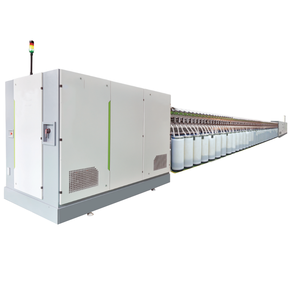

Spinning simplex machines, a cornerstone in the textile industry, play a pivotal role in yarn production. These machines, also known as roving frames, bridge the gap between carding and spinning, transforming slivers into rovings ready for the final spin. Their precision engineering ensures the consistency and strength of the yarn, which is crucial for various fabric applications.

Types and Applications

The versatility of spinning simplex machines is evident in their various types, each tailored to specific yarn requirements. From cotton to synthetic fibers, these machines cater to a wide range of materials. The application of these machines spans across the textile industry, from clothing to home furnishings, indicating their integral role in fabric production.

Technical Features and Materials

Simplex frames are designed with advanced features to ensure the efficiency of the roving process. Constructed from durable materials, these machines withstand the rigors of continuous operation. Their components are crafted to minimize maintenance needs while maximizing longevity, ensuring a seamless production process.

Advantages of Modern Simplex Machines

Modern spinning simplex machines offer numerous advantages, including enhanced speed and improved roving uniformity. Their sophisticated control systems allow for precise adjustments, which is essential for maintaining the quality of the yarn. Additionally, the integration of automation in these machines has significantly reduced manual intervention, leading to higher productivity levels.

Choosing the Right Spinning Simplex Machine

Selecting the appropriate spinning simplex machine requires consideration of several factors, such as the intended fabric type and production scale. For those new to weaving, simpler models may suffice, while experienced weavers might opt for machines with advanced features to create complex patterns. Space constraints should also be taken into account to ensure the machine fits comfortably within the designated area, allowing for efficient operation.

Conclusion

In conclusion, the spinning simplex machine is a critical investment for textile producers seeking to enhance their yarn quality and production efficiency. Alibaba.com serves as a comprehensive source for these machines, connecting buyers with a diverse range of suppliers to meet their specific textile manufacturing needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4