Introduction to Shoe Sole Making Machines

Shoe sole making machines are integral components in the footwear manufacturing industry, designed to streamline the production of various types of shoe soles. These machines have evolved significantly, transforming from simple manual tools to advanced automated systems that enhance efficiency and precision in shoe sole fabrication.

Types and Applications

The variety of shoe sole making machines caters to a broad spectrum of footwear, from casual trainers to formal brogues. Each machine type is tailored to specific applications, ensuring that whether for constructing robust boot soles or delicate sandal bases, there is a machine fit for the task. The adaptability of these machines allows for their use in diverse production environments, accommodating different materials and design complexities.

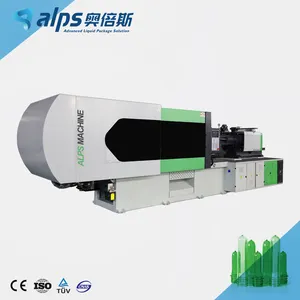

Features and Technical Specifications

Modern shoe sole making machines boast features that enhance production capabilities, such as programmable logic controllers (PLCs), precision molds, and advanced cutting and pressing technologies. These technical specifications are crucial for manufacturers to understand, as they directly impact the efficiency and quality of the shoe soles produced. Machines vary in size and capacity, making it essential to select one that aligns with the operational scale and space constraints of the workshop.

Materials and Durability

Shoe sole making machines are designed to handle a variety of materials, including rubber, PVC, and polyurethane, among others. The durability of these machines is paramount, as they must withstand the rigors of continuous operation while maintaining the integrity of the shoe soles produced. Manufacturers prioritize robust construction and longevity in machine design to ensure a reliable production process.

Advantages of Automation in Sole Manufacturing

The automation provided by shoe sole making machines offers numerous advantages, such as increased production speed, consistent quality, and reduced labor costs. Automated machines minimize the risk of human error and enhance the safety of the manufacturing process. By expediting production timelines, these machines play a pivotal role in meeting market demands and improving the overall efficiency of shoe manufacturing operations.

Choosing the Right Machine on Alibaba.com

Alibaba.com presents a comprehensive collection of shoe sole making machines, accommodating the needs of global footwear manufacturers. The platform's filter functions assist in narrowing down options based on specific requirements, such as machine size and function. With a focus on connecting buyers with a network of suppliers, Alibaba.com facilitates the sourcing of machines that align with the production goals and capacity of businesses in the footwear industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4