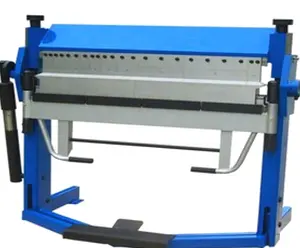

A sheet metal bender also known as a brake is used to make big right angles as well as curved folds. The robust nature of auto sheet metal bender machines is due to the fact they are manufactured using high-grade raw materials. Brake sheet metal bender provides an effective way of making products with different shapes used for different processes. High pressure exerted on the metal part causes it to deform and take the desired shape or bend. There are many various types of sheet metal benders for sale on the market, including metal sheet bending machines, busbar bending-cutting-punching machines, hydraulic sheet metal benders, mechanical profile benders, hydraulic hand and motorized pipe benders, sheet folding machines, DIY hydraulic sheet metal benders, and pipe benders, among others.

Features of a sheet bending machine

The sheet metal bender tools guarantee simplicity and are an efficient way of forming new products. Ultimate sheet metal bending is an operation that involves using forces to change the shape of a sheet. The sheet metal bender plan structure mainly includes a tool holder, a worktable, a clamping feeding device, and a CNC operating table. This is done to achieve the desired form or shape for a manufacturing process. The industrial sheet metal bender worktable is made up of a base and a clamping piece feeding structure. The workpiece is clamped and positioned on the worktable before being supplied to the processing position by the feeding mechanism, and the bending tool is operated by the tool holder to process the workpiece.

Advantages of a sheet metal bender

Benchtop sheet metal benders are used to make big right angles as well as curved folds. The bench vice sheet metal benders are also used to shape metals in the required shape and size. Metal pieces are first fixed onto the clamping device that holds them during the entire operation. DIY sheet metal benders can complete the shape of non-right angle, right angle, circular arc, pressing dead edge, etc. Portable sheet metal bender gh speed, high production efficiency, and low energy consumption High degree of automation, simple operation, no need to replace the upper and lower mold, save time.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4