Understanding the Versatility of Screws in Industry

Screws are fundamental components in various industrial applications, serving as essential fasteners that hold materials together securely. Their design allows for easy application and removal, making them a staple in construction, manufacturing, and assembly processes. The diversity of screws, including self tapping screws, concrete screws, and wood screws, caters to specific needs based on the materials they are intended to bind.

Types and Applications of Screws

The types of screws available are as varied as their applications. For instance, self tapping bolts are designed to tap their own thread into the material, providing a strong grip in metals and plastics. On the other hand, drywall screws are specifically designed for fastening drywall panels to metal or wood studs. In heavier construction, screw jacks are employed to support heavy loads, adjustable through their threaded shafts.

Features and Materials

Screws are crafted from a range of materials, each selected for its properties relative to the intended application. Stainless steel, carbon steel, and brass are common, providing varying degrees of strength, corrosion resistance, and conductivity. The geometry of the screw head also varies, with designs like the Phillips head screwdriver being a popular choice due to its self-centering feature, which reduces slippage and enhances the ease of installation.

Advantages of Using the Right Screw

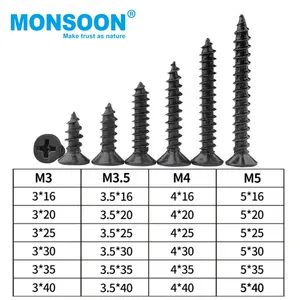

Selecting the appropriate screw for a task can significantly impact the efficiency and durability of the connection. Advantages include ease of installation with tools like a Phillips screwdriver, and the reliability of specialized screws such as self threading screws that cut their own thread and reduce the need for pre-drilled holes. The use of a screw gauge ensures the correct sizing of screws, which is critical for maintaining the integrity of the connection.

Innovations in Screw Design

Innovation in screw technology has led to the development of products like the worm screw, which provides high load-bearing capabilities in compact spaces. Similarly, sheetrock screws have been optimized for better grip and reduced material damage. The evolution of screw extractors also reflects the industry's commitment to not only constructing but also maintaining and repairing with efficiency.

Conclusion

The screw is more than just a simple fastener; it is a critical component engineered to meet the demands of modern construction and manufacturing. With a vast array of types like self tapping screws and concrete screws, and the tools designed for their application, such as the Phillips screwdriver, the industry is equipped to handle challenges with precision and strength. The selection available on Alibaba.com encompasses a wide range of these indispensable items, ready to meet the needs of any project.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4