What is Printing Mesh For Screen Printing

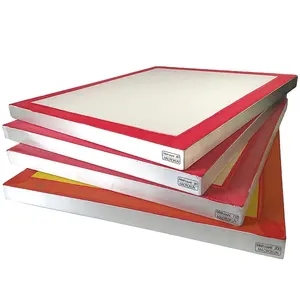

Printing mesh for screen printing is a specialized material used in the process of transferring images, designs, or patterns onto various substrates. Commonly made from polyester, these meshes are woven in a way that allows ink to pass through the openings, creating a stencil-like effect. The open areas of the mesh allow the ink to be applied to the substrate, which is then either heat set or UV cured to permanently affix the design to the surface.

Screen printing is a popular method for transferring images onto textiles, but it is also widely used for printing on paper, plastic, metal, and other materials. The versatility of screen printing allows it to be utilized by a broad range of users, from small independent garment decorators to large manufacturing plants. The process involves creating a stencil of the design, securing it onto the mesh screen, and then using a squeegee to press ink through the mesh and onto the substrate.

The properties of printing mesh such as the size of the openings (which determines the fineness of detail in the print), the material used (which can range from monofilament polyester to multifilament nylon), and the weave type (which can be anything from plain to various intricate patterns) all play a crucial role in the final outcome of the print. As a result, screen printing mesh is engineered to withstand the stresses of repeated printing and washing cycles, ensuring longevity and reliability for businesses and consumers alike.

Types of Printing Mesh for Screen Printing

The selection of printing mesh is determined by several factors including the type of printing, the ink used, and the substrate material. Here are some common types:

-

Polyester Monofilament Mesh: This type is widely used due to its excellent tensile strength and low elongation. It is suitable for printing fine details and is often used in electronic circuit boards and solar cell manufacturing.

-

Polyester Multifilament Mesh: Offering a smoother surface than monofilament, this mesh type is typically used for high-end graphics that require a very fine level of detail and is favored in the fashion industry for its drape and feel.

-

Nylon Mesh: Known for its elasticity and durability, nylon mesh is often used for printing on uneven surfaces or for working with heavy inks. It's also found in applications requiring high tension like outdoor advertising banners.

-

Stainless Steel Wire Mesh: For industrial applications such as filtering inks or paints, stainless steel wire mesh provides a robust solution that can withstand heavy use and resist corrosion.

How to choose Printing Mesh For Screen Printing

When choosing printing mesh for screen printing purposes, businesses must consider several factors to ensure they procure a material that meets their specific needs:

-

Material Composition: The choice between polyester and nylon will depend on the type of printing process and the desired print quality. Polyester mesh is generally preferred for its durability and high tension resistance, making it suitable for detailed or high-volume prints. Nylon mesh may be chosen for its flexibility and ability to handle varied substrates.

-

Mesh Count: The mesh count refers to the number of openings per inch (or centimeter), with a higher number indicating a finer mesh weave. A finer mesh is necessary for detailed designs or images but may require more careful handling during the printing process.

-

Thread Diameter: The thickness of the threads affects the mesh's durability and its ability to hold tension. A thicker thread diameter will offer more stability but may limit the detail that can be captured in a print.

-

Stencil Compatibility: Ensure that the chosen mesh is compatible with your stencil's emulsion coating and exposure times to achieve desired results.

Businesses should also consider additional services like after-sales support or online technical assistance when selecting a printing mesh on Alibaba.com.

About Printing Mesh For Screen Printing on Alibaba.com

Alibaba.com stands out as an international wholesale marketplace that brings together a vast selection of printing mesh suitable for various commercial applications. Businesses looking to source high-quality screen printing mesh will find Alibaba.com an invaluable resource due to its extensive network of suppliers offering products that cater to all aspects of this industry. From polyester and nylon mesh suitable for apparel manufacturing to stainless steel wire mesh ideal for industrial applications, there is something available for every need.

The platform's user-friendly interface allows businesses to efficiently filter through options based on material composition, weave type, elasticity, and other key attributes. This ensures that they can find products that match their specific requirements without hassle. Moreover, with services like Trade Assurance that protect buyers until delivery completion, businesses can shop with confidence knowing that their orders are secure.

Choosing Alibaba.com means tapping into a global market where you can easily communicate with suppliers in your local language and take advantage of features that streamline mobile purchasing and order handling. Whether you are starting a new venture or expanding an existing one, Alibaba.com offers tailored solutions that help businesses around the world achieve their commercial objectives with ease.

Common FAQs for Printing Mesh For Screen Printing

What is the primary advantage of using a printing mesh over other methods?

Printing meshes offer high precision and control, which is crucial for achieving detailed designs without distortion. They also provide a consistent quality across multiple print runs, which is beneficial for businesses with high-volume printing needs.

How do I determine the correct mesh size for my screen printing project?

The mesh size required depends on the level of detail and ink density you wish to achieve. Finer mesh sizes are best for intricate designs and detailed images, while larger mesh sizes are suitable for bold prints with fewer details.

Can printing meshes be used for all types of screen printing?

While screen printing is versatile, the suitability of a printing mesh for your project will depend on factors such as the type of ink used, the detail level of the design, the fabric or substrate it's being printed on, and the desired finish.

Are there different types of printing meshes for different screen printing techniques?

Yes, there are various types of printing meshes designed for different screen printing techniques. For instance, polyester mesh is commonly used for silk screen printing, while nylon mesh is better suited for digital textile printing.

How long can a screen printing mesh last before it needs replacement?

The lifespan of a screen printing mesh depends on several factors including the type of ink used, the frequency of use, and how well it's maintained. With proper care, these meshes can last for a long time.

Is it possible to print on materials other than fabric using screen printing meshes?

Yes, screen printing meshes can be used on a variety of substrates such as paper, plastic, and metal, provided they are flat and can absorb ink effectively.

What are the differences between monofilament and multifilament screen printing meshes?

Monofilament screens are thin and flexible, allowing for detailed prints but are less durable, whereas multifilament screens are more robust and can withstand repeated use and washing. The choice depends on the printing precision required and the life expectancy of the mesh.

How does humidity affect screen printing mesh?

Screen printing mesh is made from woven fabric, which can absorb moisture from the air. High humidity can cause the mesh to become saturated with moisture, affecting print quality and consistency.

Can screen printing meshes be customized based on size and shape?

Yes, screen printing meshes can be cut to size according to specific printing requirements, making them suitable for unique projects or custom-sized screens needed for special applications.

Are there eco-friendly options available for screen printing mesh?

There are eco-friendly options available such as mesh made from organic cotton or recycled polyester. These materials offer sustainable choices for businesses looking to minimize their environmental impact.

How should screen printing mesh be stored to maintain its quality?

Screen printing mesh should be stored in a cool, dry place away from direct sunlight. It should also be kept flat or rolled carefully to prevent creasing or distortion.

Can screen printing meshes be recycled at the end of their life cycle?

Screen printing meshes can be recycled at the end of their life cycle. They should be separated from other materials and processed through appropriate recycling channels.

What is a 'mesh count' and how does it affect screen printing?

The 'mesh count' refers to the number of threads or wires per inch in a mesh screen. A higher mesh count indicates more threads per inch and results in a finer print quality but may require more pressure to push ink through.

How does the ink color affect the choice of screen printing mesh?

The color of the ink can influence the print appearance and may dictate the type of mesh that is most suitable. Lighter colors typically require more detailed meshes to preserve the design, while darker colors can use coarser meshes.

What after-sales services are typically provided with wholesale screen printing mesh?

After-sales services can include online support, video technical support, and engineers available for field maintenance and repair services. However, these services may vary by supplier.

What is 'knockout' in terms of screen printing mesh preparation?

'Knockout' is a process used to create a stencil by hand or machine that is used to apply designs onto the surface of a printing substrate. It is one of the methods used in screen printing mesh preparation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4