What is Evaporator Rotary

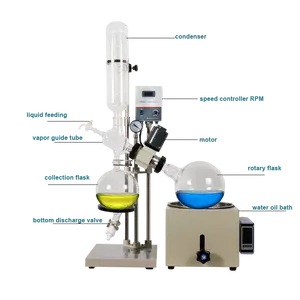

Evaporator rotary is an essential component in the field of laboratory equipment, particularly for scientific research and industrial applications that involve the concentration or separation of materials. This device is designed to evaporate or concentrate samples through the controlled application of heat, reduced pressure, or both. It is commonly used in analytical chemistry, where it is employed for tasks such as sample drying, solvent concentration, or the purification of compounds.

The principle behind the evaporator rotary process is based on the physical properties of the sample and the solvent. By adjusting temperature and pressure within the chamber, or by introducing a vacuum, the solvent can be made to evaporate from the sample. The efficient design of the evaporation chamber ensures that the process can be carried out with precision and safety. The equipment is often found in the settings like research labs, quality control labs in industries, and educational institutions.

Evaporator rotarys come in various sizes and configurations to accommodate different volumes of samples. They are equipped with features such as digital temperature control, speed settings for the rotation of the evaporation flask, and safety mechanisms. These allow for a wide range of applications while ensuring the safety of both the operator and the equipment.

Types of Evaporator Rotary

Evaporator rotaries come in several designs tailored to different applications and industries:

-

Falling Film Evaporator: This type features a film of liquid that is spread thinly over the surface of heat exchangers where it can be heated and vaporized. It is commonly used in food processing and chemical production for the continuous evaporation of liquids.

-

Wiped Film Evaporator: In this variant, a thin film of liquid is created on a surface that is wiped clean by a set of blades. This design is often chosen for its ability to handle viscous materials and is commonly found in the petrochemical and pharmaceutical industries.

-

Thin Film Evaporator: Also known as a wipe film evaporator, this equipment is optimized for the evaporation of heat-sensitive or oxidation-prone materials. It is frequently used in applications such as essential oil extraction or in electronics manufacturing.

-

Forced Circulation Evaporator: Here, the liquid is pumped through the system while being evaporated. This type is ideal when rapid evaporation is needed and is often selected for high-boiling point solvents.

How to choose Evaporator Rotary

When selecting an evaporator rotary for your business needs on Alibaba.com, consider several factors to ensure you get the most suitable equipment for your operations:

-

Applicable Industry: Choose an evaporator rotary that aligns with your industry's requirements. For example, if you're in the food processing industry, you may need a stainless steel unit that meets specific hygiene standards.

-

Core Components: Evaluate the core components such as motors, PLCs (Programmable Logic Controllers), pressure vessels, engines, and bearings. Durability and reliability of these components are crucial for continuous operation.

-

Local Service Location: Consider the location where you need the equipment. This can impact your decision due to serviceability and support varying by region.

-

Customized Support: Depending on your operation's unique needs, you might require customized features like OEM (Original Equipment Manufacturer) support or ODM (Original Design Manufacturer) services which allow for tailored equipment design and integration into existing systems.

-

Material: The material construction—such as stainless steel or 304 stainless steel—can affect the durability and suitability of the evaporator rotary for certain applications.

By considering these factors in relation to your specific industry and application context—whether it's for a manufacturing plant, farm, hotel use, or others—you can make an informed decision when purchasing an evaporator rotary through Alibaba.com.

About Evaporator Rotary on Alibaba.com

For businesses seeking reliable laboratory equipment, Alibaba.com stands out as a premier marketplace offering an extensive selection of evaporator rotary devices. With its diverse range of products catering to different scientific and industrial applications, Alibaba.com facilitates finding exactly what you need within a short span of time. The platform's commitment to connecting buyers with reputable suppliers ensures that each transaction is conducted with a focus on trust and quality.

The site's user-friendly interface allows businesses to filter products based on key specifications such as core components, local service location, power source, and key selling points. This ensures that you can find products that align closely with your requirements without hassle. Additionally, Alibaba.com provides services like Trade Assurance that protect your payments until your order is fulfilled to your satisfaction.

Choosing Alibaba.com as your source for high-quality evaporator rotary devices means access to cutting-edge technology from global leaders in lab equipment. It streamlines procurement processes while also offering customized solutions through OEM support—making it an excellent choice for businesses looking to equip their facilities with dependable tools for research or commercial use.

Common FAQs for Evaporator Rotary

What is an evaporator rotary?

An evaporator rotary is a device used to concentrate and vaporize liquids through the application of heat and a vacuum, by a rotary mechanism similar to that of a centrifuge.

How does an evaporator rotary work?

An evaporator rotary operates by creating a partial vacuum within a chamber, then heating the liquid to its boiling point. This reduces the pressure on the liquid and allows the more volatile components to vaporize.

What industries commonly use evaporator rotarys?

Evaporator rotarys are commonly used in industries such as food and beverage production, chemical processing, pharmaceutical manufacturing, and environmental technologies like wastewater treatment.

What are the benefits of using an evaporator rotary?

Evaporator rotarys offer high energy efficiency, precise process control, and are capable of handling a wide range of liquids and applications compared to other types of evaporators.

Can an evaporator rotary be customized for specific applications?

Yes, many suppliers offer customized support such as OEM, ODM, and OBM services which allow businesses to tailor an evaporator rotary to their specific needs and applications.

Are there different types of evaporator rotarys available?

Yes, there are various types of evaporator rotarys including single-stage pump systems, plate heat exchangers, and multi-stage pumps. Each type is designed for specific operating conditions and applications.

How do I determine the right size of an evaporator rotary for my business?

The size of an evaporator rotary required depends on the volume of liquid to be processed and the desired production rate. It's important to choose a system that can handle your operational demands efficiently.

What should I consider when choosing an evaporator rotary for my business?

Consider the type of liquid being processed, operational efficiency, ease of cleaning, material construction for durability, and whether the system offers customization support.

What are the maintenance requirements for an evaporator rotary?

Maintenance requirements can vary depending on the type and usage intensity of the rotary. Generally, regular cleaning and periodic inspections are necessary to ensure optimal performance and longevity of the system.

Can an evaporator rotary be used for both heating and cooling applications?

Some types of evaporator rotaries can be used for both heating and cooling applications. It's important to select a model designed specifically for the type of operation required.

What safety features should I look for in an evaporator rotary?

Look for safety features such as automatic shut-off, pressure and temperature alarms, and overcurrent protection to ensure safe operation and prevent damage to the equipment.

How energy-efficient are evaporator rotarys?

Evaporator rotarys are known for their energy efficiency due to their design which minimizes heat loss and can be further optimized with programmable controls.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4