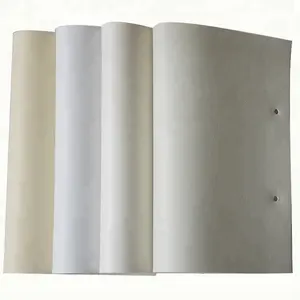

Rexine leather, a type of synthetic leather, is crafted through a detailed manufacturing process. The process begins with mixing raw materials such as PVC (polyvinyl chloride) or polyurethane (PU) with pigments to achieve a solid form. For PVC rexine, the material is then coated onto a fabric base, creating a two-layered structure with a PVC surface and a fabric backing. This base material undergoes a foaming process in a high-temperature production line, which thickens the PVC layer, doubling its initial thickness.

Following the foaming, the material is embossed with textures using an embossing roller, which imprints designs onto the PVC surface. The final steps involve surface treatments, such as color adjustment or printing patterns, to enhance the aesthetic appeal. An alternative method involves using release paper, which transfers texture to the PVC layer, followed by the application of glue to adhere the PVC to the backing fabric, resulting in the finished rexine leather product.

PU rexine leather is produced differently, with no foaming or calendering needed. The backing fabric is first made wet, then coated with a mixed polyurethane material. The coated fabric passes through a solution containing DMF (N,N-Dimethylformamide) to solidify the PU. After removing the toxic DMF through washing and drying, a surface PU layer is applied. This layer, coated on release paper, is half-dry and sticky, and upon baking, the release paper is removed to reveal the final PU rexine leather.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4