Introduction to PVC Granule Making Machines

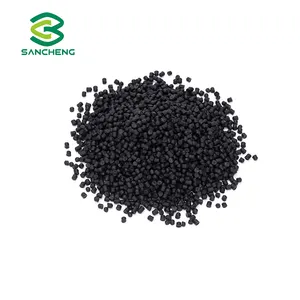

Plastic granulation plays a pivotal role in the recycling and manufacturing sector, particularly in the transformation of plastics for repurposing. Among the array of equipment essential for this process, PVC granule making machines stand out. These machines are engineered to convert recyclable plastic materials into fine granules, which can then be utilized to fabricate new plastic products, thereby fostering a sustainable production cycle.

Types and Applications

The versatility of granulation equipment is evident in the variety of models available. From robust, heavy-duty machines to compact units suitable for smaller operations, each type serves a specific function. Thermoforming granulators cater to high-temperature applications, while edge trim granulators complement extrusion processes. The granules produced are ideal for injection molding and other manufacturing techniques, ensuring efficient reuse of plastic waste.

Features and Materials Processed

Plastic recycling machines are not limited to a single type of plastic. While predominantly used for PET and PP materials, advanced models are capable of processing a range of plastics including PVC, LET, and LDPE. This adaptability makes them a valuable asset in various manufacturing settings, where different plastic types are used.

Advantages of Utilizing Granulators

The implementation of a plastic granulator machine in a manufacturing environment is a step towards eco-friendly practices. By converting waste into reusable granules, these machines significantly reduce the need for new raw materials. Moreover, they contribute to the efficiency of production lines by enabling a closed-loop recycling system, where waste is continuously reintegrated into the production process.

Complementary Recycling Equipment

For a comprehensive recycling approach, integrating plastic shredders with granulators can be highly effective. Shredders are adept at handling more resilient materials, broadening the scope of recyclable inputs. This combination ensures that a wider array of plastic waste can be reclaimed and repurposed.

Selecting the Right Machine

Choosing the appropriate PVC granule making machine is crucial for optimizing recycling operations. Factors such as input material, volume of production waste, and desired granule size play a significant role in the selection process. The extensive catalog on Alibaba.com provides a platform for businesses to connect with suppliers, ensuring they find a machine that aligns with their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4