What is Pvc Edge Banding Machine

PVC edge banding machines are specialized equipment designed for applying a band made of PVC (polyvinyl chloride) edge banding to the edges of various boards and panels. These machines are an essential component in the furniture and woodworking industries, where they serve the dual purpose of providing a clean, finished look to the edges of products and protecting them from wear and tear. The banding material itself is a type of plastic that can be matched to the color or grain of the underlying material, making it an attractive option for designers and manufacturers who desire a cohesive aesthetic in their products.

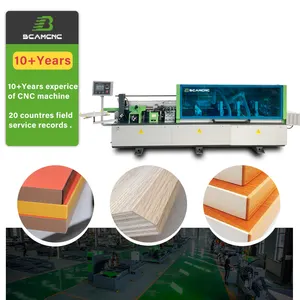

The operation of a PVC edge banding machine is based on the application of a heated element, typically a metal banding with a PVC coating, which is pressed onto the edge of a substrate material. This process can be carried out manually or with automatic machinery that feeds the banding material from a roll into the machine's heating element. The heat softens the PVC, allowing it to be pressed onto the edge with a strong adhesive bond. Some advanced machines also include features like pre-milling (to ensure a clean edge), end trimming (to cut off excess banding), and scraping systems (to smooth out any rough edges).

PVC edge banding machines are intended for businesses that require efficiency and precision in their edge banding process. They cater to a wide range of users, from small carpentry workshops to large furniture factories. These machines are designed to be user-friendly with various settings that can be adjusted to suit different production requirements. They are also engineered for reliability and ease of maintenance to minimize downtime and maximize productivity.

Types of PVC Edge Banding Machine

PVC Edge Banding Machines come in different types to accommodate various needs and requirements in the market. The diversity of these machines ensures that there is a solution for every aspect of edge banding, from small manual units to sophisticated automated systems:

-

Manual Edge Banding Machines: Ideal for small workshops or DIY enthusiasts, these machines are handheld or table-mounted. They require the user to feed the edge banding material manually and often feature a guillotine-like cutter for trimming the excess. Manual machines are chosen for their simplicity and cost-effectiveness.

-

Automatic Edge Banding Machines: These are used in manufacturing plants where high-volume edge banding is required. They can include conveyor systems for moving the material through the process, PLC controls for programmable operations, and multiple heads to handle different band thicknesses or materials.

-

Semi-automatic Edge Banding Machines: A middle ground between manual and fully automatic machines, semi-automatic machines still require some human intervention but automate the feeding and cutting processes. They can be more efficient than manual machines while offering a lower cost than fully automated systems.

-

Portable Edge Banding Machines: Designed for on-the-go or space-restricted users, portable edge banding machines offer mobility without compromising on performance. These machines can be moved between job sites or workshops as needed.

-

Hot Melt and Pressure Sensitive Adhesive (PSA) Edge Banding Machines: These machines use heat and pressure to activate a thermo-reactive adhesive on the edge band material. Hot melt machines are common for wood and cabinet door edge banding tasks while PSA machines are used for pre-glued or self-adhesive edge banding.

How to choose Pvc Edge Banding Machine

Choosing the right PVC edge banding machine for your business involves considering several factors related to your specific needs and production volume. Here's what you should keep in mind:

-

Production Volume: The quantity and frequency of use will determine whether you need a simple manual machine for occasional applications or a fully automatic production line for continuous high-volume processing.

-

Material Compatibility: Ensure that the machine you select is capable of handling various thicknesses and types of PVC. Some machines may also be designed with adjustable temperature controls for different melting points.

-

Edge Quality: For high-end products or customer-facing surfaces, you'll want an edge banding machine that produces clean, durable edges with minimal chance of peeling or bubbling.

-

Efficiency and Speed: Consider how quickly you need to process your materials. Fully automatic machines are much faster but also more expensive; manual machines offer more control but at a slower pace.

-

After-Sales Service: Given that purchasing an edge banding machine represents a significant investment, choose a supplier that provides comprehensive after-sales support including installation, training, and maintenance services.

About Pvc Edge Banding Machine on Alibaba.com

For businesses seeking reliable PVC edge banding machines, Alibaba.com stands out as a global wholesale marketplace that connects buyers with an extensive network of suppliers. With an array of options tailored to various manufacturing needs and specifications, Alibaba.com provides an efficient solution for sourcing high-quality edge banding machines that cater to an assortment of industries including furniture manufacturing, construction material shops, and many more.

Alibaba.com's platform offers an intuitive shopping experience where buyers can explore detailed product listings from various suppliers around the world. The convenience of filtering through features such as core components, key selling points, and applicable industries allows businesses to pinpoint exactly what they need. Moreover, Alibaba.com's commitment to facilitating international trade is evident through services like Trade Assurance which enhances buyer confidence by ensuring payment security until delivery completion.

Choosing Alibaba.com as your source for wholesale PVC edge banding machines not only offers variety but also reliability; suppliers on this platform are verified ensuring they meet certain quality standards. As a business owner looking to streamline your operations or expand your product offerings, you can leverage Alibaba.com's comprehensive services to stay ahead in your industry while maintaining peace of mind regarding transaction security and supplier trustworthiness.

Common FAQs for Pvc Edge Banding Machine

What is PVC edge banding used for in manufacturing?

PVC edge banding is primarily used to finish the exposed edges of furniture and other items, providing both protection and an aesthetically pleasing transition between the material and the core of the item.

Can PVC edge banding be applied to any material?

PVC edge banding is versatile and can be applied to a variety of materials, including particleboard, MDF, plywood, and other substrates suitable for edge finishing.

How does a PVC edge banding machine work?

A PVC edge banding machine typically consists of a feeding system to move the material, a heating element to activate the adhesive, and pressure rollers to ensure a secure bond between the PVC edge band and the workpiece.

What types of pressure rollers are used in PVC edge banding machines?

Pressure rollers can vary in material composition, size, and design. They are often made of steel or rubber and come in different configurations to apply pressure evenly across the PVC edge band during the process.

Are there different grades of PVC edge banding available?

Yes, there are different grades available that vary in terms of quality and application. It is important to select a grade that is appropriate for the specific manufacturing requirements of your products.

What should I consider when choosing the size of a PVC edge banding machine?

Consider the dimensions of the material you will be processing and the desired output volume. Machines come in various sizes suited for different production needs.

Is it possible to get custom-designed PVC edge banding tailored to my specifications?

Many suppliers offer customization options for PVC edge banding machines where you can specify dimensions, materials, and additional features to meet your unique requirements.

How do I ensure consistent quality when using a PVC edge banding machine?

To ensure consistent quality, follow the machine manufacturer's guidelines for operation and maintenance. Also, use high-quality materials and check the machine's calibration regularly.

Do I need special training to operate a PVC edge banding machine?

While operating a PVC edge banding machine does not typically require advanced training, it is important to familiarize yourself with the machine's user manual and safety precautions before use.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4