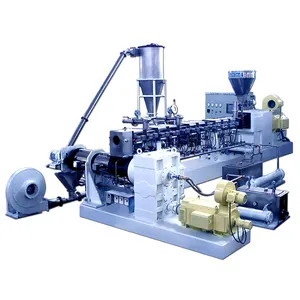

PVC Dropping Machine Overview

The realm of manufacturing is witnessing a revolution with the advent of PVC dropping machines, a category of equipment designed for the efficient production of PVC products. These machines are pivotal in the creation of a myriad of items by accurately dispensing PVC material into precise molds. The automation of PVC dispensing has streamlined production processes, ensuring consistency and reliability in the manufacturing of PVC goods.

Types and Applications

There are various types of PVC dispensing machinery tailored to diverse industry needs. From small-scale operations to large manufacturing lines, these machines facilitate the production of items ranging from intricate keychains to robust automotive parts. The application of these machines spans across sectors, including but not limited to, the creation of promotional goods, apparel accessories, and 3D labels. The versatility of PVC liquid dispensing machines makes them indispensable in settings where precision and volume are paramount.

Features and Materials

The construction of a PVC dropping machine involves hardened metals, ensuring endurance against rigorous use and external factors. These machines are equipped with advanced features such as automated fuel injection and K-series linear bottle blowing capabilities, enhancing their operational efficiency. The materials used in the manufacturing of these machines are selected for their durability and compatibility with the PVC dispensing process, ensuring long-term functionality and minimal maintenance.

Advantages of Modern PVC Dropping Machines

Modern PVC dropping equipment boasts numerous advantages, including energy efficiency and the ability to produce a wide range of product sizes and shapes. The precision offered by these machines minimizes waste and increases the quality of the final product. Additionally, the eco-friendly nature of some models aligns with the growing demand for sustainable manufacturing practices. The integration of automated systems within these machines also allows for ease of operation, making them accessible to a broader range of users.

Choosing the Right Machine

Selecting the appropriate PVC dropping machine involves considering factors such as capacity, size, and specific feature requirements. Alibaba.com hosts a vast array of options, ensuring that purchasers can find a machine that aligns with their operational needs and production goals. The variety available on the platform caters to both specialized and general manufacturing tasks, with each machine designed to offer efficiency and adaptability in PVC product creation.

Operational Excellence and Sustainability

The PVC dropping machines available on Alibaba.com are not only designed for operational excellence but also for sustainability. These machines are conducive to creating a range of products, from beverage bottles to condiment containers, without compromising on environmental responsibility. The commitment to providing equipment that adheres to eco-friendly standards reflects the evolving landscape of industrial manufacturing and the push towards greener practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4