Exploring the Versatility of Power Hammer Dies

Within the realm of metalworking, power hammer dies stand as a pivotal category, essential for shaping and forging metals with precision and efficiency. These components are integral to various forging machines, each designed to meet specific industrial needs. Understanding the nuances of these dies is crucial for professionals seeking to optimize their metalworking processes.

Types of Forging Machines Utilizing Power Hammer Dies

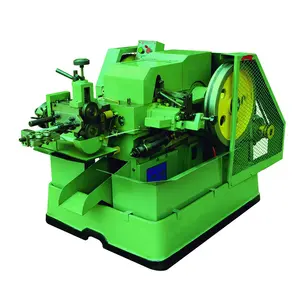

The landscape of forging equipment is diverse, with each type of machine harnessing power hammer dies for different applications. Horizontal forging machines, for instance, employ horizontal movements to shape bar stock, relying on a crank gear system for operation. In contrast, vertical forging machines, which move the tool vertically, are suited for smaller forgings such as hooks and knife blanks, operating without a direct connection to a crank gear mechanism.

Forging rolls and rotary forging machines represent other categories where power hammer dies are crucial. Forging rolls focus on enhancing production efficiency during the forging process, while rotary forging machines are adept at hot drawing and swaging, utilizing rotational movements to shape metals with precision.

Applications and Features of Power Hammer Dies

Power hammer dies are not limited to a single application but are versatile tools used across various metal shaping processes. They are instrumental in the production of components ranging from simple agricultural tools to complex automotive parts. The efficiency of these dies is evident in their ability to handle repetitive heating cycles, which is essential for producing items like axes and propellers.

The design features of power hammer dies contribute to their widespread use in the industry. They are crafted to withstand the rigors of metal forging, ensuring durability and consistent performance. The compatibility of these dies with different forging machines also adds to their appeal, allowing for a seamless integration into existing production lines.

Materials and Advantages of Power Hammer Dies

The construction of power hammer dies involves robust materials capable of enduring the high-stress environment of metal forging. The choice of material impacts the die's longevity and effectiveness, with common selections including hardened steel and alloys tailored for high-impact resistance.

The advantages of utilizing power hammer dies are manifold. They significantly enhance production rates, contribute to the manufacturing of precise metal shapes, and support the creation of complex geometries with minimal waste. This efficiency not only streamlines production but also contributes to the economic viability of metalworking operations.

Choosing the Right Power Hammer Dies

Selecting the appropriate power hammer dies is a critical decision that influences the quality and efficiency of the forging process. Factors such as the type of metal being forged, the desired end product, and the specific forging machine in use all play a role in determining the most suitable die. Professionals in the metalworking industry can explore a comprehensive selection of dies on Alibaba.com, ensuring they find the right match for their forging needs without the influence of brand bias.

In conclusion, power hammer dies are indispensable tools in the metal forging industry, offering versatility, durability, and precision. While exploring options on Alibaba.com, buyers can make informed decisions based on the detailed information provided, ensuring they procure dies that align with their specific industrial requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4