Grasping the complexities of electrical connections is essential for maintaining safety and operational efficiency in any electrical infrastructure. A power cord terminal serves as a pivotal element, engineered to link a wire with a compatible counterpart such as a terminal block, board, or other interfaces demanding a steadfast electrical bond. These terminals are available in a plethora of forms and are widely employed across a vast array of applications, from household electronics to heavy-duty industrial power systems.

Types and Characteristics of Power Cord Terminals

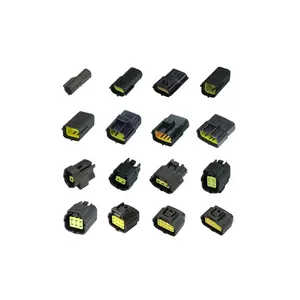

There exists a broad spectrum of power cord terminals to suit diverse applications and wire dimensions. Ring terminals ensure a robust connection to screws and bolts, whereas spade terminals facilitate a semi-permanent bond that can be readily detached. Hook terminals, crafted to avert inadvertent disconnections, bear resemblance to spade terminals. Quick-disconnect terminals are prized for their swift assembly and disassembly, an asset in systems that necessitate regular maintenance. Butt terminals, on the other hand, join wires from end to end, forging a stable inline bond. Each variant exhibits distinct features, such as the spade terminals' varying tongue widths, which must align with the respective stud sizes. The selection of terminal type not only influences installation convenience but also the dependability and durability of the electrical linkage.

Structure and Operation of Power Cord Terminals

The architecture of a power cord terminal is meticulously crafted to optimize electrical flow and mechanical firmness. A conventional terminal comprises a conductive body, typically copper, paired with an insulating sheath. The body features a barrel into which the stripped wire is inserted and crimped, securing both a mechanical and electrical linkage. Premium terminals boast a seamless barrel that mitigates splitting and ensures a robust crimp. Certain terminals also incorporate an inspection window, permitting visual assurance of complete wire insertion prior to crimping. The insulating sleeve, often color-coded, not only safeguards the connection but also provides a handle for manipulation and may be composed of materials like PVC or nylon, each offering a different equilibrium of pliability and sturdiness.

Materials and Properties

The constituents of power cord terminals are chosen for their conductive and resilient characteristics. Copper reigns as the predominant conductive material, favored for its superior electrical conductivity and ductility, which facilitates secure crimping. The selection of a plating substance, such as tin, silver, or gold, hinges on the desired conductivity, anti-corrosive properties, and endurance. Insulating substances like PVC proffer flexibility and sound insulating traits, while nylon is lauded for its exceptional resistance to heat and aging. The amalgamation of these materials guarantees that the terminal can endure electrical and mechanical pressures while preserving a steadfast connection throughout its service life.

Business Usages and Applications

Power cord terminals play a vital role across various sectors, including the automotive industry, where they find use in wiring harnesses, and within consumer electronics, for internal device connections. In the realm of manufacturing, they enable the construction of electrical panels and machinery. The terminal choice can markedly influence the efficiency of production lines and the dependability of the end product. For example, the industrial sector values quick-disconnect terminals for their user-friendliness, which can significantly curtail downtime during maintenance. The deployment of these terminals not only streamlines manufacturing processes but also bolsters the safety and reliability of electrical frameworks, thereby enhancing the intrinsic value of business operations.

Functions and Tasks

The principal role of a power cord terminal is to forge a steadfast juncture between a wire and an electrical interface. They are tailored to transmit current with minimal resistance or heat production. Specialized terminals, tailored for high-voltage scenarios, are designed to thwart arcing and cope with the rigors of abrupt power fluctuations. The functionality of these terminals is crucial in settings ranging from simple lighting systems to intricate data centers, where a stable and reliable electrical bond is of the utmost importance.

Features and Unique Selling Points

Salient features of power cord terminals include designs that prioritize user-friendliness, such as ergonomically crafted sleeves that ease handling and crimping. Certain terminals also boast attributes like resistance to vibration, indispensable in the automotive and aerospace sectors. The unique selling propositions of high-caliber terminals encompass adherence to industry benchmarks, such as UL or CE certification, providing users with assurances of their safety and dependability. These certifications often become a pivotal factor for businesses in component procurement, as they necessitate confidence in the performance of these critical elements in their applications.

Benefits and Positive Outcomes

Employing the appropriate power cord terminal yields a multitude of advantages, including enhanced safety through reliable connections that diminish the likelihood of electrical fires. They also improve the performance of electrical apparatus by ensuring a consistent connection that minimizes energy dissipation. For enterprises, this equates to energy cost reductions and diminished maintenance expenditures owing to the enduring nature of the connections established by these terminals.

How to Use and Operate Effectively

Effective utilization of power cord terminals commences with the selection of the correct terminal for the wire gauge and intended use. The wire should be stripped to the proper length, inserted into the terminal's barrel, and crimped with the appropriate tool to guarantee a secure bond. It is critical to avoid over-crimping, which can compromise the wire and terminal, or under-crimping, which may lead to a precarious connection.

How to Choose the Right Model

Selecting the optimal power cord terminal model entails evaluating the electrical demands of the application, the environmental conditions it will encounter, and the spatial limitations of the installation site. The wire type and its insulation should also be considered when choosing between insulated and non-insulated terminals. Consulting with a seasoned supplier or referring to industry norms can assist in making an enlightened choice.

How to Clean and Maintain

To clean and maintain power cord terminals, it is imperative to keep them devoid of dust and corrosion. Routine inspections are advised to identify signs of wear or damage, and any accumulated debris should be meticulously cleared from the terminal area. Adhering to the manufacturer's maintenance instructions is essential for prolonging the life of the terminals.

How to Install

The installation of power cord terminals necessitates the appropriate crimping instrument, which must be compatible with the terminal type and size. The wire must be prepared in accordance with the terminal's guidelines before crimping. Subsequent to crimping, a pull test is recommended to confirm the terminal's secure attachment to the wire. Proper installation is imperative for the electrical system's safety and efficacy.

Target Audience and Meeting Needs

The intended audience for power cord terminals encompasses electricians, engineers, and technicians across sectors such as automotive, aerospace, consumer electronics, and industrial manufacturing. These professionals demand dependable terminals that satisfy precise technical specifications and conform to industry standards. High-quality terminals address these requirements by offering an assortment of choices that cater to varying electrical capacities, environmental conditions, and installation contexts.

What are the key considerations when selecting a power cord terminal for industrial use?

In an industrial context, pivotal factors when choosing a power cord terminal include the terminal's current and voltage capacity, exposure to environmental elements like temperature extremes or chemicals, and the mechanical strains it must endure. The simplicity of installation and the availability of suitable crimping tools are also essential considerations.

How does the color coding of power cord terminals aid in installation?

The color coding of power cord terminals streamlines installation by offering an immediate visual cue to ascertain the terminal's size and capacity, which corresponds to the wire gauge. This strategy aids in averting mismatches between terminal and wire size, which could result in insecure connections or potential safety risks.

What are the best practices for ensuring a secure connection with power cord terminals?

To ensure a secure connection with power cord terminals, best practices include employing the proper crimping tool and die set for the terminal in use, verifying that the wire is correctly stripped and inserted into the terminal, and conducting a pull test to check the crimp's security. Additionally, selecting terminals that are appropriate for the wire gauge and adhering to the manufacturer's guidelines are vital for a dependable bond.

For enterprises in search of premium electrical components, Alibaba.com presents an extensive array of power cord terminals to fulfill diverse industrial requirements. With detailed product overviews and technical specifications, Alibaba.com enables business purchasers to make informed decisions when seeking efficient and trustworthy electrical solutions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4