Pork Skin Cutting Machine: An Overview

The pork skin cutting machine is an essential piece of equipment in the meat processing industry, particularly for businesses involved in producing pork-based products. This machinery is designed to efficiently remove the skin from pork, a step that is crucial for the preparation of various pork items. The efficiency of a pork skin cutter machine can significantly streamline the production process, enhancing overall productivity.

Types and Applications

There are several types of pork skin cutters available on the market, each serving a specific need within the meat processing sector. Manual cutters are hands-on tools that require the operator to physically handle the meat. Automatic cutters, powered by electricity, offer a more hands-off approach, increasing throughput with less manual labor. The flywheel option presents a balance, allowing for manual control with the ease of a hand-cranked wheel. These machines are not only used for preparing meat for sausages but are also vital in creating cuts for other pork products.

Features and Materials

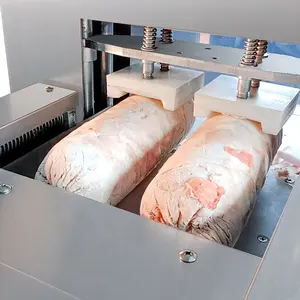

A pork skin cutter machine is typically constructed from durable materials such as stainless steel, ensuring longevity and ease of cleaning. The blades are designed for precision, allowing for consistent cuts without damaging the meat. Some models feature adjustable settings to accommodate different skin thicknesses and are equipped with safety features to protect the operator.

Advantages of Using a Pork Skin Cutter

Utilizing a pork skin cutting machine in meat processing operations can lead to increased efficiency, as it automates a task that is labor-intensive and time-consuming when done manually. This automation can contribute to a faster production rate and a more uniform product, which is crucial for businesses looking to scale operations. Additionally, the precision of a pork skin cutter can help in reducing waste, thereby maximizing the use of raw materials.

Choosing the Right Machine

Selecting the appropriate pork skin cutter involves considering the volume of production, the available space in the processing area, and the specific requirements of the pork products being produced. It is important to assess the machine's capacity, speed, and maintenance needs to ensure it aligns with operational goals.

Integration into Production Lines

Incorporating a pork skin cutter machine into an existing production line should be done with consideration to workflow and efficiency. The machine should complement other equipment, allowing for a seamless transition from skinning to further processing stages, such as slicing or packaging.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4