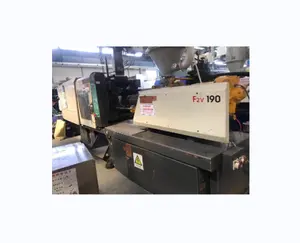

Introduction to Plastic Wall Plug Making Machines

Plastic wall plug making machines are specialized equipment used in the manufacturing of plastic wall plugs, an essential component in the construction and electrical industries. These machines are designed to mold plastic materials into precise and durable wall plugs used for securing screws in walls. The process involves plastic injection molding, where plastic pellets are melted and injected into pre-designed molds to form the final product.

Types and Applications

There are various types of plastic injection molding machines tailored to meet different production requirements. These machines are pivotal in producing a wide array of plastic wall plugs, each designed to cater to specific load-bearing capacities and wall materials. The versatility of these machines allows for their application in creating not only wall plugs but also a range of PVC pipe fittings and other construction-related accessories.

Features and Materials

A plastic wall plug making machine is equipped with a specialized screw design that enhances plasticization, ensuring efficient material flow and high-quality product output. The materials used in the production of wall plugs typically include polyethylene (PE) and polyvinyl chloride (PVC), known for their durability and resistance to various environmental factors. These machines are capable of handling different plastic materials, allowing manufacturers to produce wall plugs suitable for diverse applications.

Technical Advantages

The technical advantages of using a plastic wall plug injection machine include precision in production and the ability to withstand significant machining forces, thanks to their robust clamping systems. With clamping forces that can range significantly, these machines can accommodate various mold sizes, leading to efficient production cycles and the ability to meet large-scale industrial demands.

Operational Efficiency

Operational efficiency is a hallmark of the plastic wall plug production machine. These machines are designed for ease of operation, with automated features that reduce manual intervention and streamline the production process. The efficiency of these machines not only lies in their automation but also in their contribution to recycling efforts, as they can repurpose plastic waste into functional products.

Choosing the Right Machine

Selecting the appropriate plastic wall plug manufacturing machine is crucial for businesses looking to optimize their production. Factors such as production capacity, material compatibility, and specific product requirements should be considered. While Alibaba.com serves as a platform to connect buyers with a diverse range of suppliers, it is essential to assess the specifications and capabilities of each machine to ensure it aligns with your manufacturing goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4