What are Shredder Blades For Plastic Recycling

Shredder blades for plastic recycling are precision tools designed to cut, shred, or granulate plastic waste into smaller pieces, which can then be melted and reprocessed into new plastic products. These blades are essential components in the plastic recycling industry, serving a wide range of businesses that require the use of recycled plastic materials in their manufacturing processes. The materials commonly include post-consumer plastics from various sources such as bottles, containers, and packaging, as well as pre-consumer plastics from industrial scrap such as car bumpers, pipes, and films.

The primary function of shredder blades for plastic recycling is to facilitate the breakdown of plastic items into more manageable pieces. This process is vital because the smaller the pieces, the easier it is to melt them down and reform them into new products. The blades themselves are made from materials like tool steel or industrial-grade carbide, which ensures longevity and durability. The design and configuration of the blades will vary depending on the type of plastic being shredded and the specific requirements of the equipment.

Shredders work on the basic principle of cutting or grinding materials. Depending on the type of shredder, the plastic is either cut with rotating blades or crushed with a combination of blades and rollers. This action not only reduces the size of the plastic waste but also increases the surface area available for melting, thus optimizing the efficiency of the recycling process. Proper blade maintenance and replacement are critical for consistent performance and to avoid contamination of the recycled material.

Types of Shredder Blades for Plastic Recycling

In the realm of plastic recycling, several types of shredder blades are used to handle different materials and tasks. Each type has unique characteristics suited for particular applications:

-

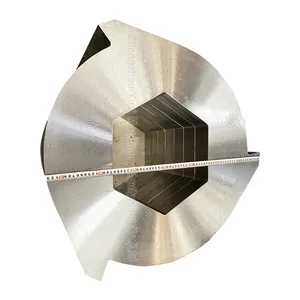

Single Shaft Shredder Blade: This type features a single rotating shaft with cutting blades that are adept at handling large or bulky plastic items. They are often used for continuous shredding tasks in industrial settings.

-

Dual Shaft Shredder Blade: Dual shaft shredder blades have two cutting shafts that rotate in opposite directions. This design is typically more robust and can handle more challenging materials and higher volumes, making it suitable for tougher recycling jobs.

-

Four Shaft Shredder Blade: As the name suggests, these shredder blades have four cutting edges and can further reduce plastic items into smaller pieces. This type is ideal for highly secure data destruction and is commonly found in environments where sensitive information is handled.

-

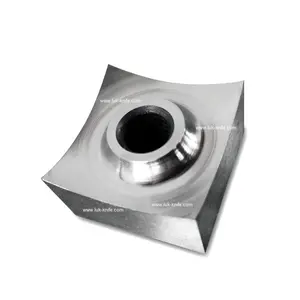

Granulator Blade: While not a shredder, granulator blades are worth mentioning as they work in conjunction with a granulator machine to cut down plastic into fine particles that can be melted down to create new products.

-

Pipe Shredder Blade: Specifically designed for cutting down large plastic pipes, these blades often feature reinforced structures and are capable of handling the tough demands of industrial pipe recycling.

Each type of blade is tailored for different material properties and industrial requirements, ensuring that businesses can find the right solution for their specific shredding needs.

How to choose Shredder Blades For Plastic Recycling

Selecting the right shredder blades for plastic recycling involves several considerations based on the types of plastics being processed, the required output size, and the specific nature of the waste. For businesses looking into wholesale options on Alibaba.com, it's crucial to assess:

-

Plastic Type: Identify whether you are processing standard thermoplastics like PP (polypropylene) or engineering plastics such as ABS (acrylonitrile butadiene styrene). The hardness and composition of the plastic will determine which blade type is most suitable.

-

Output Size: The end-product requirements will influence the choice of blades. Industrial buyers often need a range of sizes for different applications from coarse shredding to fine granulation.

-

Machine Compatibility: Ensure that the blades selected are compatible with your specific machine model in terms of mounting, material construction (e.g., carbon steel, stainless steel), and cutting mechanisms (e.g., dual shaft, single shaft).

-

Regulatory Compliance: For businesses operating in certain regions or industries with strict regulations, it's important to choose blades that meet specific standards for safety and environmental impact.

By carefully evaluating these factors against the types of blades available on Alibaba.com, businesses can make an informed decision that aligns with their operational needs and quality expectations.

About Shredder Blades For Plastic Recycling on Alibaba.com

Alibaba.com stands as a global marketplace that connects businesses with a vast selection of shredder blades suitable for every kind of plastic recycling need. With over two decades of experience in facilitating B2B transactions across multiple industries, Alibaba.com has established itself as an essential resource for companies seeking specialized equipment and components like shredder blades.

The platform's extensive network of suppliers ensures that businesses can find blades tailored to their unique requirements – whether they're shredding large volumes of plastic or processing materials with high precision. From double shaft shredder blades suited for heavy-duty applications to single-use options for more light-duty operations, Alibaba.com offers a comprehensive range that caters to all industry needs.

Moreover, Alibaba.com's commitment to secure transactions through services like Trade Assurance provides businesses with peace of mind when purchasing. The site's user-friendly interface allows for easy browsing and communication in local languages while mobile compatibility ensures that buyers can conduct business on-the-go with convenience. With Alibaba.com's dedication to helping small and medium-sized businesses thrive through online trade solutions, companies can rely on finding reliable suppliers for all their shredder blade needs while benefiting from competitive pricing and potential customization options.

Common FAQs for Shredder Blades For Plastic Recycling

What types of materials can shredder blades be used on?

Shredder blades are designed to handle a wide range of materials including plastics, paper, cardboard, wood, and various metals. The specific type of blade required will depend on the material being processed and the desired outcome.

How often do shredder blades need replacement?

The frequency of blade replacement depends on the volume of work and the type of material being processed. It's essential to inspect blades regularly for wear and tear and replace them when they are no longer effective.

Can shredder blades be resharpened?

Yes, some shredder blades can be sharpened to extend their lifespan. However, the ability to be resharpened depends on the material and hardness of the blade.

Are there shredder blades suitable for heavy-duty industrial use?

Industrial shredder blades are available that are specifically designed to withstand the rigors of heavy-duty use in manufacturing plants and industrial settings.

Is it possible to get custom-designed shredder blades?

Custom-designed shredder blades can be obtained through suppliers that offer OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) services, allowing businesses to tailor blades to their specific needs.

What should be considered when choosing a shredder blade for a granulator?

When choosing a shredder blade for a granulator, consider the material it's intended to shred, the machine's specifications for blade compatibility, and the type of granulator (central or inline) being used).

Are there any safety measures that need to be taken when operating shredder blades?

Safety measures when operating shredder blades include wearing appropriate personal protective equipment, ensuring the machine is stable during operation, avoiding loose clothing or items that could get caught in the shredder, and following all manufacturer guidelines.

How do I ensure the longevity of my shredder blades?

To ensure the longevity of your shredder blades, use them only for their intended purpose, follow proper maintenance schedules, and always use a sharp blade to prevent wear and tear on the machine.

Can multiple types of shredder blades be used on the same machine?

Some shredder machines are designed to accommodate various types of blades for different materials. Check your machine's manual or consult the supplier for information on compatibility to use multiple blade types.

What is the importance of after-sales service provided by suppliers?

After-sales service provided by suppliers can be crucial for ensuring continuous and efficient operation of your shredder. Services such as video technical support, online support, and field maintenance are helpful for troubleshooting and maintaining your equipment.

How does Alibaba.com ensure the quality of shredder blades sold on its platform?

While Alibaba.com does not manufacture or guarantee products itself, it provides a platform where buyers can review supplier information, customer feedback, and utilize Alibaba.com's Trade Assurance service for added transaction protection.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4