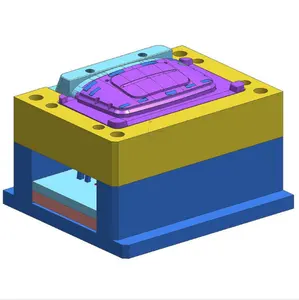

Plastic Mould Injection Mold Professional 3d Design Mould Service Manufacturer Plastic Injection Mold

Plastic Mold Making Design CNC Maker Injection Plastic Mold For Plastic Injection Molding Part Service Injection Mould

Plastic lens molds are integral components in the manufacturing of precision lenses used across various industries. These molds are crafted to shape plastic into specific configurations for lenses, ensuring the final product meets exacting standards. The versatility of plastic injection molds allows for high customization, catering to the diverse needs of businesses seeking to produce anything from intricate optical components to larger, more decorative elements.

The application of plastic lens molds spans numerous sectors, including automotive, consumer electronics, and healthcare. In automotive, they are used to create clear, durable lenses for lighting and instrumentation. Consumer electronics utilize these molds for cameras, smartphones, and other devices requiring high-quality lens components. In healthcare, they are essential for producing the clear components of medical devices. The type of mold selected—be it a single-cavity mold for bespoke items or a multi-cavity mold for high-volume production—depends on the project's scale and complexity.

When selecting a mold for plastic lenses, material choice is paramount. The durability and finish of the mold material directly impact the quality of the lens. Options range from hardened steel for longevity to aluminum for faster heat dissipation and cycle times. Each material offers distinct advantages, and the choice often hinges on the specific requirements of the lens being produced, such as its optical clarity, strength, and resistance to wear.

The precision of injection mold design ensures that each lens produced is consistent with the next, which is crucial for applications where optical clarity and fit are critical. The use of precision plastic molds also allows for rapid production without sacrificing the lens's quality, providing an efficient solution for businesses looking to scale operations.

Customization is a significant advantage when procuring plastic lens molds. Suppliers on Alibaba.com can tailor molds to specific design requirements, ensuring that the end product aligns with the client's needs. Simultaneously, standardizing certain elements of the mold, such as lift bars and clamp slots, can streamline the manufacturing process, especially when producing a series of related products.

Alibaba.com hosts a vast array of suppliers offering mold manufacturing services to suit any requirement. Without advocating for any single supplier, the platform facilitates connections between businesses and manufacturers, ensuring a diverse selection of molds to meet the precise needs of any lens production endeavor. By leveraging the detailed information provided by suppliers, buyers can make informed decisions to find the right mold solutions for their plastic lens manufacturing needs.