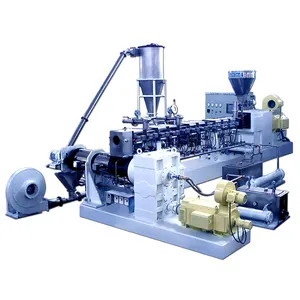

A plastic extruder machine is a high-performance industrial equipment designed to process plastic materials into a continuous profile. It works by melting and reshaping raw plastic granules or pellets, forcing them through a shaping die to form a plastic material of uniform shape. This machine typically consists of a large, rotating screw that fits tightly against a cylindrical barrel, a hopper for feeding the raw materials, a heater to melt the plastic, and a die that shapes the molten plastic. The extruder machine is versatile and is used in various applications such as pipe/tubing, weather stripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. It is an essential piece of equipment in the plastic manufacturing industry due to its efficiency, precision, and ability to create complex shapes.

Different types of plastic extruder machines

Extrusion machines come in various types to cater to different industrial needs. The PVC extrusion machine and PVC pipe extruder are specifically designed to produce PVC pipes used in construction, plumbing, and electrical conduit applications. On the other hand, a sheet extruder or plastic sheet extruder is used to manufacture plastic sheets that are widely used in packaging and thermoforming applications. Lastly, there are specialty extruders like the pin extruder and the planetary roller extruder, designed for specific applications such as wire coating or producing good-quality sheets and films. Each type of plastic extruder machine has its strengths and limitations, catering to a wide range of industrial needs.

Applications of plastic extruder machines

The applications of a plastic extruder are diverse and vast. For instance, a pipe extruder or pipe extrusion machine is used in the production of plastic pipes. Similarly, a plastic pipe extrusion machine is used for manufacturing pipes for various industries such as agriculture, construction, and utilities. Additionally, these machines are used in the production of plastic coatings for numerous products, such as wires and cables. Plastic extruder machines are also applied in the recycling of plastic waste, transforming it into reusable material. Their versatility and efficiency make them a cornerstone in the plastic industry.

Features and benefits of plastic extruder machines

The plastic extruder machine offers several features and benefits. It can work with a variety of plastic materials, ranging from PVC to PET. Moreover, it can produce products in various shapes and sizes, catering to a broad spectrum of industrial needs. The plastic extruder machine is also known for its efficiency and precision, ensuring consistent product quality. Furthermore, advancements in technology have led to the development of recycled plastic extruder machines that can process recycled plastic, contributing to environmental sustainability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4