What is pet Film Cost Guide

Pet film, an acronym for polyethylene terephthalate film, is a type of plastic known for its high tensile strength and excellent thermal stability. This versatile material is often used in the production of flexible electronics, where it serves as a substrate for the incorporation of electronic components. It is also commonly found in the packaging industry, where it is utilized for items such as food, pharmaceuticals, and cosmetics, due to its protective qualities against moisture, oxygen, and light.

The production of pet film involves several steps, including the polymerization of ethylene glycol and terephthalic acid to form the raw material polyethylene terephthalate (PET), which is then melt-extruded through a flat die to create a film. The film can be oriented or stretched in the longitudinal (machine direction) or transverse direction (cross-machine direction) to enhance its mechanical properties. The orientation process aligns the molecules in the PET film, making it stronger and more durable.

Businesses across various industries use pet film due to its unique combination of properties. It is lightweight, has good resistance to water and most organic solvents, and is highly transparent. These attributes make it particularly suitable for applications such as consumer goods packaging, electrical insulation, and as a material for creating labels and stickers. The cost of pet film can vary depending on its thickness, size, and additional treatments like UV stabilization or heat resistance.

Types of Pet Film Cost Guide

PET films come in various types to cater to different needs within the market. Each type offers unique characteristics suited for specific uses:

-

Coated PET Films: These are PET films with a coating applied to one or both sides. The coating can be added to enhance the film's properties such as heat resistance, adhesion, or moisture barrier capabilities. They are often used in applications like labels, tapes, and advanced packaging solutions.

-

Uncoated PET Films: Uncoated PET films do not have any additional coatings, making them ideal for applications where the inherent properties of PET are sufficient. They are commonly used in products like photovoltaic cells, as well as in outdoor signs and displays.

-

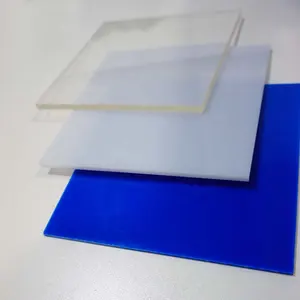

Clear PET Films: These films are entirely transparent and offer high clarity, which is essential for products that require showcasing their contents without any visual distortion. They are frequently used in window displays or as protective layers on consumer electronics.

-

Opaque PET Films: Opaque films provide complete light blockage and are used where light sensitivity is an issue. They work well as protective layers in applications where light transmission is to be minimized or where an opaque background is needed for labeling purposes.

How to choose pet Film Cost Guide

When selecting pet films for resale or commercial use, businesses should consider several factors to ensure they meet their customers' needs effectively. The type of pet film is crucial; options like BOPP, BOPET, and BOPETG have distinct characteristics suited for different applications.

Businesses should consider the intended use case for the product—whether it's for industrial packaging or consumer goods—and select a type that matches these requirements. For example, if the film is intended for high-strength applications in industries like construction or shipping, a BOPETG with its superior tensile strength may be most appropriate.

The thickness of the film is another important consideration; it should be chosen based on the product's weight and rigidity needed. Thicker films will generally offer more protection but may be less flexible and more challenging to seal.

Additionally, businesses must take into account the clarity and transparency needed for their products. For instance, for retail packaging that requires a clear view of the product, opting for a BOPP could be ideal due to its clarity and glossiness.

Lastly, specific features such as anti-static properties or flame retardancy might be necessary depending on the product's end-use. Understanding these requirements will help businesses choose the right type of pet film for their needs while also satisfying their clients' expectations.

About pet Film Cost Guide on Alibaba.com

Alibaba.com stands out as a global marketplace that connects businesses with a comprehensive range of PET film suppliers from around the world. The platform offers an extensive selection of PET film products catering to diverse industrial needs while emphasizing flexibility and customization options. With advanced filtering tools available on the website, buyers can easily navigate through choices based on features like thickness, application type, processing service offered, and much more.

The website's user-friendly interface allows buyers to communicate with suppliers directly and negotiate terms that best fit their specific requirements. Additionally, Alibaba.com's Trade Assurance service provides peace of mind by securing payments until delivery is confirmed satisfactory. This assurance is particularly valuable for businesses investing in bulk orders or specialized products.

Choosing Alibaba.com as your sourcing platform means accessing one of the largest online B2B marketplaces where you can find high-quality PET film products tailored to your needs—whether you're packaging food or electronics or seeking heat-resistant materials for industrial applications. The platform's dedication to facilitating easy global trade is evident through its multilingual support and mobile-friendly shopping experience. With Alibaba.com's vast network of suppliers and commitment to quality and security in every transaction, businesses can confidently procure the right PET films at competitive rates without compromising on service or product variety.

Common FAQs for pet Film Cost Guide

What is the primary function of pet films in packaging?

Pet films serve as protective barriers that are used to package and protect a wide range of products including food, pharmaceuticals, cosmetics, and various other consumer goods from environmental factors such as moisture, light, and dust.

How do thickness and width of pet films impact their performance?

The thickness of a pet film impacts its strength and barrier properties. Width determines the film's coverage area and whether it can be used to seal products effectively, while thickness relates to the film's durability and the rigidity it provides.

Can pet films be customized based on specific business needs?

Yes, pet films can be customized in terms of thickness, width, and functionality to suit the unique requirements of different businesses and applications.

What are the advantages of using recycled pet films?

Recycled pet films offer environmental benefits by reducing waste and energy consumption in production. They can also provide cost savings and may be eligible for certain green certifications.

Are there pet films that are both biodegradable and recyclable?

Yes, there are biodegradable and recyclable pet films available that can help businesses meet sustainability goals while still providing effective packaging and protection for products.

How do anti-static pet films work?

Anti-static pet films are treated with special chemicals that help dissipate static electricity. They are commonly used in environments where electronic devices are protected, such as manufacturing plants or cleanrooms.

What should be considered when choosing a pet film for high-temperature applications?

For high-temperature applications, it is important to select a pet film that can withstand heat without becoming brittle or losing its barrier properties.

Is it possible to print on pet films?

Many pet films are suitable for printing applications. However, it is crucial to choose a film with a printable surface or one that allows for proper adhesion of printing materials.

What types of barriers do pet films provide?

Pet films provide barriers against moisture, oxygen, light, and dust due to their semi-impermeable qualities. The type of barrier provided depends on the specific application needs.

Can I order samples of pet films before making a bulk purchase?

Suppliers may offer samples of their pet films so businesses can evaluate the material's suitability for their applications before committing to a large order.

Are there any regulations that pet films must comply with?

Pet films may need to comply with certain regulations or certifications depending on their intended use. It is essential to check with suppliers regarding the specific standards relevant to your industry.

What is the difference between thermal lamination and pouch lamination?

Thermal lamination involves bonding together two or more layers with heat-activated adhesive, while pouch lamination creates a sealed package with pre-applied adhesive that requires no extra heat during application.

How does the choice of pet film impact the shelf life of packaged products?

The right choice of pet film can significantly extend the shelf life of packaged products by protecting them from factors such as moisture, light, heat, and oxygen that can degrade their quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4