What is Fragrance Manufacturing System

Fragrance manufacturing systems are sophisticated industrial setups designed for the production of various types of fragrances, perfumes, and colognes. These systems are the backbone of the fragrance industry, providing a platform for the large-scale creation and blending of aromatic compounds that contribute to the pleasant and distinctive scents we associate with personal care products, home goods, and fine fragrances. The manufacturing of fragrances involves a precise interplay of science and art, where experts carefully balance the chemical composition of the fragrance to achieve a particular olfactory effect.

These systems cater to a wide range of clientele, from individual entrepreneurs looking to launch their own fragrance line, to established businesses in the beauty and personal care sectors that require large volumes of a consistent product. The operation of fragrance manufacturing systems is based on several key principles, including the extraction or synthesis of fragrance oils, the blending of these oils to create specific scent profiles, and the preservation of the final products.

The manufacturing process typically begins with the extraction of essential oils from natural sources such as flowers, fruits, spices, and woods. For those who prefer a more sustainable approach, advances in technology have also led to the development of synthetic fragrances made from petrochemicals. Once essential oils or synthetic components are obtained, they undergo a precise blending process to create the final fragrance. This can include adding solvents or diluting agents to adjust the strength and longevity of the scent. The mixture is then carefully controlled to ensure consistency across batches.

Types of Fragrance Manufacturing System

Fragrance manufacturing systems come in various forms to cater to different aspects of the industry's requirements. Here's a brief overview of some common types:

-

Batch Processing Systems: These systems are designed for small-scale production and typically involve mixing fragrance oils with alcohol and other solvents. They are versatile and can be used to produce a wide range of scents.

-

Continuous Processing Systems: These systems are used for large-scale production and involve a continuous flow of materials and solvents. They are ideal for high-demand fragrance manufacturing where large quantities of scented products need to be produced rapidly.

-

Micro-Emulsion Systems: A relatively new addition to the fragrance manufacturing lineup, these systems use micro-emulsion technology to create stable blends that can be easily dispersed in water-based applications.

-

Industrial Spray Systems: These are specialized systems that allow for precise control over the application of fragrances. They are commonly used in settings like hotels and restaurants to create a welcoming environment.

-

Customizable Fragrance Machines: Offering flexibility in scent selection and intensity, these systems allow for the creation of custom fragrances tailored to specific preferences or commercial uses.

How to choose Fragrance Manufacturing System

Selecting the right Fragrance Manufacturing System is crucial for businesses aiming to produce high-quality fragrances efficiently. Here are some considerations for choosing a system that aligns with your company's needs:

-

Scalability: Consider the expected growth of your business. A modular system that can be easily expanded or upgraded may offer more flexibility as your production needs increase.

-

Product Variety: Evaluate the range of products you intend to manufacture. Some systems are optimized for specific types of fragrances (e.g., fine, synthetic, or natural), while others offer more flexibility across different scent profiles.

-

Ingredient Quality: The system should be compatible with a wide range of ingredients—both for fragrance creation and for product formulation. This ensures that you can maintain high standards for ingredient sourcing and product quality.

-

Regulatory Compliance: Fragrance manufacturing systems should meet all relevant industry regulations, especially those pertaining to safety and environmental impact.

-

After-sales Support: Reliable after-sales service options such as online support or availability of engineers should be considered to ensure continuity of operations.

About Fragrance Manufacturing System on Alibaba.com

For businesses seeking reliable fragrance manufacturing systems, Alibaba.com stands out as an exceptional global marketplace connecting buyers with a vast network of suppliers. The platform's extensive range of fragrance making equipment caters to varied business needs across multiple industries including retail shops, hotels, restaurants, and cosmetic companies. With an emphasis on versatility and adaptability, businesses can find machinery tailored to their specific requirements whether they operate on a small scale or large commercial enterprises.

Alibaba.com's commitment to facilitating seamless transactions is reflected in services like Trade Assurance which safeguards payments until delivery is confirmed. This level of support empowers businesses to invest in their operations confidently knowing they have protection against unforeseen circumstances. The platform's user-friendly interface allows buyers to communicate with suppliers in their local language and manage orders efficiently on mobile devices.

Furthermore, Alibaba.com’s recognition as a trusted hub for B2B trade is underscored by its ability to attract suppliers offering a wide array of products across nearly 5,900 categories. This diversity combined with the platform's focus on quality assurance makes Alibaba.com not just a marketplace but a partner invested in providing tailored trade solutions that help businesses thrive in the competitive world of fragrance manufacturing.

Common FAQs for Fragrance Manufacturing System

What is a Fragrance Manufacturing System?

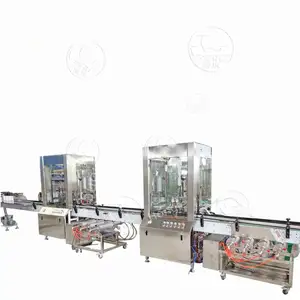

A Fragrance Manufacturing System is an automated production line specifically designed for creating, compounding, and dispensing fragrances in a repeatable and efficient manner. It is used in various industries such as food & beverage, personal care, home care, and more.

How does a Fragrance Manufacturing System work?

A Fragrance Manufacturing System operates by using precise dispensing systems to mix the correct amounts of fragrance with a base solution, which are then used in products. It can be controlled through software for consistent quality and efficiency.

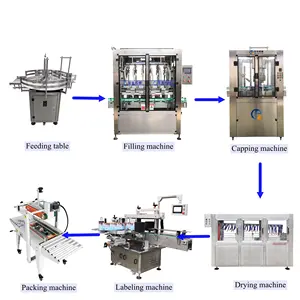

What are the key components of a Fragrance Manufacturing System?

Key components typically include a mixing vessel, a base solution or solvent, a dispensing head, a cooling tunnel, and a control system. These may vary depending on the specific type of system.

Who can use a Fragrance Manufacturing System?

Businesses involved in the production of perfumes, colognes, and other scented products, as well as suppliers of raw materials and individual entrepreneurs looking to create custom fragrances, can use a Fragrance Manufacturing System.

What types of fragrances can be produced using a Fragrance Manufacturing System?

Fragrance Manufacturing Systems can produce a wide range of fragrances including natural, synthetic, and hybrid scents. They can also be tailored to meet the specific requirements of the industry they are serving.

How do I choose the right capacity for my business needs?

Consider the scale of your operations and the volume of products you intend to produce. Systems with lower capacity are suitable for small businesses while those with higher capacities are better for large-scale production.

Can I produce custom fragrances for my brand with these systems?

Yes, these systems can produce custom fragrances through precise control over ingredient ratios and blending processes. Customization allows businesses to create unique scents aligned with their brand identity.

Is it possible to produce eco-friendly fragrances using these systems?

Yes, you can produce eco-friendly fragrances by selecting natural or sustainable ingredients and opting for a base solution with a minimal environmental impact.

What after-sales services are typically provided with Fragrance Manufacturing Systems?

After-sales services can include access to technical support, maintenance, repair services, and spare parts. Availability may vary depending on the supplier.

How do I ensure the quality of the fragrances produced by this type of equipment?

To ensure quality, look for suppliers with good track records, check for certifications or compliance with industry standards, and inquire about their quality control processes.

Are there any limitations to the types of scents I can produce with a Fragrance Manufacturing System?

While there is a wide range of scents that can be produced with these systems, certain base notes or accords may not be achievable due to the limitations of available ingredients or blending restrictions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4