What is Automated Paint Filling System

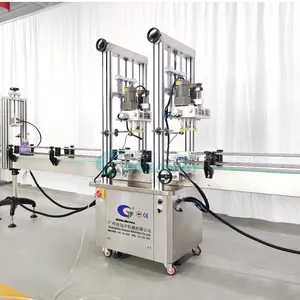

Automated paint filling systems are sophisticated machinery designed to efficiently fill containers, such as paint cans, with various types of liquid products. These systems are an integral part of the manufacturing and packaging industries, ensuring that paints are dispensed accurately and efficiently for commercial distribution. The technology behind automated paint filling systems is geared towards providing a consistent, high-quality output, reducing labor costs, and minimizing the risk of human error.

These systems operate on the principle of automation, where they perform a series of predetermined steps without direct human intervention. They are equipped with mechanisms that measure and dispense the product with precision, typically using a combination of robotics and advanced control systems. Automated paint filling systems can cater to a wide range of users, from small-scale paint shops to large manufacturing plants, providing an invaluable service in the production process.

Key components of an automated paint filling system include a PLC (Programmable Logic Controller) or a computer that orchestrates the operation of the machine. Sensors are used to detect the presence of containers and to monitor the amount of paint being dispensed. The dispensing mechanism itself is designed to handle the paint gently to avoid foaming and ensure an even application. These systems can be equipped with various features such as pressure regulators, mixers, and heating elements to control the viscosity of the paint and improve the quality of the fill.

Types of Automated Paint Filling Systems

Automated paint filling systems come in several types to suit different applications and production requirements:

-

Rotary Fillers: These systems feature a rotating plate that indexes the container under the filling nozzle. They are commonly used for high-speed filling of smaller containers such as cans or bottles.

-

Piston Fillers: Using a piston to measure and dispense paint or other liquids, these systems are versatile and can handle a range of viscosities. They are often employed in industries requiring precise measurement like automotive or aerospace parts coating.

-

Gravity Fillers: Gravity fillers use a simple process where paint flows into containers from elevated tanks without the need for additional pressure. They are suitable for filling viscous coatings into large containers or for continuous fill operations.

-

Auger Fillers: These are ideal for powders or granular materials and work by rotating an auger that scoops up the product and delivers it to the filling point. They are commonly used in the food industry or for filling nail polish bottles.

-

Net Weigh Fillers: Net weigh fillers measure weight to determine the amount of product dispensed into the container. They are highly accurate and used in applications where precise measurements are critical.

How to choose Automated Paint Filling System

Choosing the right automated paint filling system requires careful consideration of several factors that align with specific business needs. The type of system selected should reflect the volume of production, the complexity of the filling process, and the characteristics of the paints being used.

It's important to evaluate the scale of production as machinery capacity varies widely. For smaller operations or those with limited space, tabletop or semi-automatic filling systems might be sufficient. Conversely, larger manufacturing plants would benefit from fully automated systems that handle high-volume tasks efficiently.

The complexity of the filling process is another critical factor. Simple, single-component paints may only require a basic automatic system that can perform repetitive tasks accurately. In contrast, multi-component paints or intricate designs could necessitate highly specialized systems with advanced controls.

Lastly, consider the physical attributes of the paints themselves. Thicker or more viscous paints may require a more robust system with stronger components that can withstand greater wear and tear.

About Automated Paint Filling System on Alibaba.com

Alibaba.com stands out as a global marketplace where businesses can find an extensive selection of automated paint filling systems suitable for various industries and applications. With an array of options from numerous suppliers around the world, Alibaba.com facilitates the process of choosing the right system that aligns with your business requirements. Whether you need a high-precision machine for your manufacturing plant or a reliable solution for your retail store's paint section, Alibaba.com's platform offers detailed product descriptions and supplier profiles to assist you in making an informed decision.

The diversity in machinery capacity, core components, and key selling points available on Alibaba.com ensures that you can find a system tailored to your specific needs. Moreover, Alibaba.com's commitment to secure transactions through services like Trade Assurance provides peace of mind when purchasing complex equipment like automated paint filling systems.

Alibaba.com's user-friendly interface simplifies the process of locating suppliers who can offer customized solutions—whether you require semi-automatic operation for efficient paint handling or fully automated systems that minimize human error. With its vast network of suppliers and comprehensive support services including online trade solutions and after-sales service options, Alibaba.com positions itself as an indispensable ally for businesses seeking to enhance their operations with automated paint filling technology.

Common FAQs for Automated Paint Filling System

What is an automated paint filling system used for in an industrial setting?

An automated paint filling system is used to precisely and efficiently fill containers with a variety of paints and coatings in industrial applications. It ensures consistency in the filling process, which is essential for maintaining product quality and reducing material waste.

How do automated paint filling systems work?

Automated paint filling systems work by using a combination of machinery, robotics, and software to perform tasks such as container positioning, filling, and capping. They are highly efficient and can operate continuously, which is crucial for high-volume production environments.

What factors should be considered when selecting an automated paint filling system?

When selecting an automated paint filling system, consider the type of containers you will be filling, the range of paints you need to handle, the system's accuracy, speed, ease of operation, and its ability to integrate with other manufacturing processes.

How do I ensure the automated paint filling system I choose is compatible with my existing equipment?

Compatibility with your existing equipment depends on the system's design and specifications. It is important to match the operational requirements of your business with the functionalities of the automated paint filling system.

Can automated paint filling systems handle different types of paint and coatings?

Yes, automated paint filling systems are designed to handle various types of paint and coatings, including water-based, solvent-based, UV-curable, and high-solid paints.

What are the maintenance requirements for automated paint filling systems?

Maintenance requirements for automated paint filling systems vary depending on the type and frequency of use. Regular maintenance typically includes checking fluid levels, cleaning components, and ensuring moving parts are properly lubricated.

Are there industry-specific automated paint filling systems available?

Yes, there are industry-specific automated paint filling systems tailored to different sectors such as automotive, aerospace, food processing, pharmaceuticals, and more. These systems are designed with the unique requirements of each industry in mind.

Can automated paint filling systems be customized to fit specific business needs?

Many suppliers offer customization options for automated paint filling systems to meet specific business needs. These can include custom-sized containers, specific programming for unique filling processes, or additional safety features.

What types of after-sales services should I look for when purchasing an automated paint filling system?

Look for suppliers that offer comprehensive after-sales services such as online support, video technical support, and engineers available to service machinery overseas. This can ensure ongoing support and maintenance tailored to your specific needs.

How does an automated paint filling system handle different levels of viscosity in paint?

An automated paint filling system is designed to handle various viscosities through adjustable settings that allow the system to adjust the fill volume and speed accordingly.

Is it possible to integrate an automated paint filling system with other machines on my production line?

Yes, many automated paint filling systems can be integrated with other machines on a production line for a more streamlined operation. It is important to ensure that the system is compatible with your existing machinery.

What safety precautions should be considered when using an automated paint filling system?

Safety precautions may include ensuring that the system meets industry safety standards, providing proper training for operators, and having safety equipment in place. Always follow the manufacturer's guidelines for use.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4