What are Nylon Pellets For Manufacturing

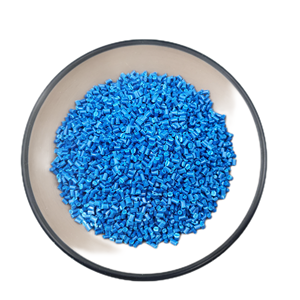

Nylon pellets are small beads or granules of nylon resin that have been melted and then cooled to form a hard, durable material. This versatile plastic is known for its high tensile strength, thermal stability, and chemical resistance, making it a popular choice in various industries. Nylon pellets are typically used in injection molding processes where they are heated until molten and then injected into molds to manufacture end products.

Nylon's unique properties lend themselves well to manufacturing processes which require materials that can withstand high temperatures and offer excellent mechanical properties. It is a lightweight material but has a high strength-to-weight ratio, which is essential for products that need to be both strong and lightweight. These pellets are also hygroscopic, which means they absorb moisture from the air, making them an excellent choice for applications where water resistance is a key requirement.

The use of nylon pellets is widespread across industries such as automotive, electrical and electronics, consumer goods, and even in the production of everyday items like zippers and screws. The pellets must be carefully selected based on the specific grade of nylon being used, ensuring that they meet all necessary specifications for the end product.

Types of Nylon Pellets for Manufacturing

Nylon pellets come in an array of types to accommodate various manufacturing needs and end-use applications. The materials differ in their properties and the manufacturing processes involved:

-

Virgin Nylon Pellets: These are made directly from raw materials without any recycled content. They are typically used for applications where purity and strength are paramount, such as in automotive components and high-performance engineering plastics.

-

Recycled Nylon Pellets: Made from reclaimed nylon waste such as discarded fishing nets or textile fibers, these pellets are an eco-friendly alternative used by companies looking to reduce their carbon footprint. Recycled nylon pellets are commonly employed in the production of sustainable fashion wear and outdoor gear.

-

Impact-Modified Nylon Pellets: These include additives that improve the toughness of nylon, making it less brittle. They are used in applications requiring resilience such as safety helmets or sports equipment.

-

Heat-Stabilized Nylon Pellets: These are specifically designed to maintain their properties at elevated temperatures, making them suitable for applications like automotive and electrical components where heat resistance is necessary.

-

Moisture-Resistant Nylon Pellets: With additives that repel water and provide moisture resistance, these pellets are ideal for outdoor applications or any product that needs to withstand exposure to moisture.

How to choose Nylon Pellets For Manufacturing

Selecting the right type of nylon pellets for manufacturing involves understanding the specific needs of your product and production process. For instance, if you're in the automotive industry and require high strength and resistance to heat and chemicals, you might opt for PA66. On the other hand, if you're in the textiles industry and need flexibility and resistance to high temperatures, you may choose PA6. For those in the consumer goods sector looking for a balance between strength and cost-effectiveness, PA12 could be an ideal choice.

Consideration should also be given to the processing method—whether it's injection molding or another form of manufacturing—as certain types of nylon are more suited to particular processes. Additionally, if you require specialized characteristics like UV resistance or electrical conductivity, these should be factored into your decision.

Finally, sustainability is becoming an increasingly important factor; therefore, choosing eco-friendly materials like biodegradable nylons may be something to consider if environmental impact is a key concern for your business.

About Nylon Pellets For Manufacturing on Alibaba.com

For businesses seeking reliable sources for nylon pellets, Alibaba.com presents an expansive marketplace that connects buyers with a global network of suppliers. With an extensive selection of nylon products suitable for various industrial applications—ranging from automotive parts to protective gear—Alibaba.com stands out as a hub where businesses can find tailored solutions that meet their specific needs.

Alibaba.com's platform simplifies international trade by offering services like Trade Assurance which secures payments until delivery is confirmed. This commitment to security enhances buyer confidence when sourcing from suppliers around the world. The platform also facilitates communication in local languages and includes mobile-friendly features that enable buyers to conduct business on-the-go.

By leveraging Alibaba.com's comprehensive system for finding quality suppliers and its user-friendly interface designed to accommodate businesses at every scale—from startups to established enterprises—buyers can efficiently locate suppliers who provide not only a wide array of products but also an assurance of support throughout their transaction journey. This dedication has established Alibaba.com as a go-to destination for wholesale nylon pellets catering to various industries' demands for dependable materials.

Common FAQs for Nylon Pellets For Manufacturing

What are the benefits of using nylon pellets in manufacturing?

Nylon pellets offer high strength, excellent flexibility, and resistance to both impact and abrasion, making them ideal for a wide range of industrial applications. Their specific properties vary based on the type of nylon used and can be tailored to suit various processing and end-product requirements.

How do I determine the appropriate type of nylon pellet for my application?

Selecting the right type of nylon pellet involves considering the end-use of the product, the processing method, the required mechanical properties, and any additional features like flame retardancy or UV resistance. It may also be necessary to match the pellet material with any regulatory compliance needed.

Can nylon pellets be customized for specific applications?

Yes, nylon pellets can be customized with different additives to enhance or modify their properties such as flame retardancy, impact resistance, or UV protection to meet the requirements of a particular application.

Are there different grades of nylon pellets available for industrial use?

Yes, there are various grades of nylon pellets available that offer different levels of purity, mechanical resistance, and performance characteristics. These grades are typically denoted as such and can be chosen based on the specific needs of the industry application.

What processing services can be applied to nylon pellets?

Processing services such as cutting, molding, and extrusion are commonly applied to nylon pellets to produce a variety of products ranging from automotive parts to electrical components. These services allow for the customization of the pellets for specific manufacturing requirements.

Are there any environmentally friendly options available for nylon pellets?

Nylon is a synthetic material, so its environmental impact depends on the recycling rate and handling of waste. Some suppliers may offer recycled nylon pellets or those made with bio-based materials that could be more sustainable choices.

How do I ensure the quality of the nylon pellets I purchase?

Quality can often be ensured by requesting detailed product specifications from suppliers, as well as machinery test reports if available. Some suppliers may also provide samples for testing purposes.

What shapes do nylon pellets come in?

Nylon pellets typically come in the form of cylindrical or oval-shaped pellets. The shape can be customized based on the processing requirements of the end-product.

Is it possible to obtain a machinery test report for nylon pellets?

Obtaining a machinery test report will depend on the supplier's capabilities. It is essential to communicate your specific testing needs clearly to ensure the report meets your standards and requirements.

Can I order a sample batch of nylon pellets before placing a bulk order?

Many suppliers offer samples of their nylon pellets so that businesses can test the quality and suitability of the material before committing to a larger purchase. Check with individual suppliers on Alibaba.com regarding their sample policies.

What should I consider when choosing a supplier for nylon pellets?

When choosing a supplier for nylon pellets, consider factors such as the supplier's production capacity, customization options, adherence to industry standards, environmental policies, and the quality of their product samples and machinery test reports.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4