Nut Bolt Making CNC Machine: An Overview

The cnc nut bolt making machine represents a category of specialized equipment designed for the production of various fastening elements. These machines harness computer numerical control (CNC) to manufacture bolts and screws with precision and efficiency. As a cornerstone in the manufacturing sector, these machines play a pivotal role in the production of standardized and custom fastening solutions.

Types and Applications

Different models of nut bolt making cnc machine cater to a wide range of applications. From small-scale workshops to large industrial settings, these machines are versatile in producing various types of threads, bolts, and screws. The adaptability of these machines allows them to be used in automotive, construction, and manufacturing industries, where precision-threaded components are crucial.

Technical Features and Materials

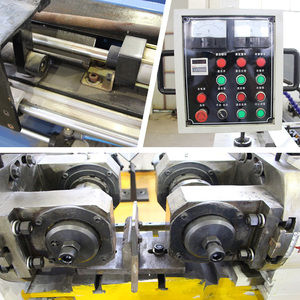

A typical nut bolt making cnc machine is equipped with dual die pieces, with the capacity to alter speeds for optimal operation. The construction of these machines often involves robust materials that contribute to their longevity and reliability. The integration of advanced motors and power distribution systems enables these machines to handle high-frequency quenching processes, essential for creating durable threaded components.

Operational Advantages

The operational efficiency of a cnc nut bolt making machine is one of its primary advantages. With options ranging from semi-automatic to fully automatic settings, these machines offer flexibility to meet diverse threading requirements. The electro-hydraulic execution function enhances the precision and speed of production, while features like self-suction and anti-fouling capabilities ensure a clean and efficient operation.

Innovative Design and Durability

Innovation is at the heart of the nut bolt making cnc machine design, allowing for the production of not only standard bolts and screws but also specialized fasteners like abnormal-shape nails and threaded nails. The durability of these machines is evident in their impact-resistant construction and wear-resistant motors, which are designed to withstand intense production demands without compromising performance.

Quiet Operation and Environmental Consideration

Modern nut bolt making cnc machine models are engineered to operate with minimal noise, making them suitable for environments where noise pollution is a concern. The low-noise operation ensures that production can proceed without causing disturbances, reflecting the manufacturers' commitment to environmental considerations in industrial settings.

Incorporating a cnc nut bolt making machine into your production line can significantly enhance your manufacturing capabilities. As you explore the options available on Alibaba.com, consider the specific requirements of your application to find a machine that aligns with your production goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4