Automatic Tapping Arm Servo Motor Thread Electric Tapping Machine M16 M36 Universal Head Self-Tapping Screw Machine

Milling Drilling Spindle High Quality 0.5kw 40000rpm High Precision Dental Milling Drilling Engraving Spindle

380v 4.5kw Electric Spindle Cnc Machine Tool Electric Spindle High-speed Electric Spindle Products

Universal Lathes Multiple Machining Capabilities With Turning Milling Drilling And Tapping Lathe Machine Widely Used

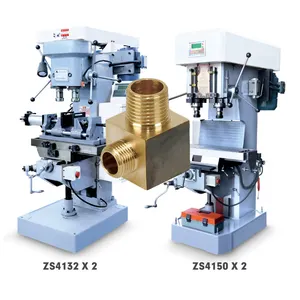

double hand automatic tapping machine multiple spindle tapping and drilling machine

Double hand automatic tapping machine multiple spindle tapping and drilling machine

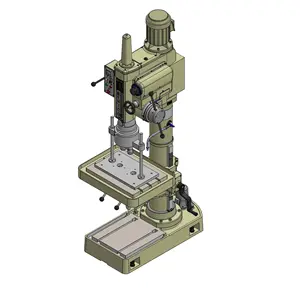

High End Design Multi Spindle Upright Drilling Tapping Machine With Square Table

LCH multiple spindles automatic gear type drilling machine electric multi head auto feed bench mounted hot tapping machine

Three spindle head multiple Multi axis tapping Multiple Spindle Drill

Small high speed automatic metal borehole cnc tapping drilling multiple spindle head mincing machine m10-m36

New Condition Overseas Service Provided Multi Axial Multiple Spindle Head Tapping Machine Vertical Hydraulic Drilling Machine

Industrial portable pneumatic double spindle multiple fully multi spindle cnc tapping machine automatic drill tapping machine

Z5040C/1 portable magnetic drill press multi spindle rail column upper vertical drilling machine

Horizontal CNC Machine 8 spindles with 4th axis for processing multiple holes of angle valve

Variable Speed Automatic Stand Metal Vertical Multiple Spindle Drilling Machine

High precision multiple fasteners drilling press machines 4 spindles nut tapping Machine

multiple spindle tap machine

New Vertical Air Tapping Machine Nc Multiple Spindle Head Position Tapping Machine

Small high speed automatic metal borehole cnc tapping drilling multiple spindle head mincing machine m10-m36

Customizable Aluminum Die Casting Drilling Tapping Machine Multi Spindle Multi Directional Drilling Tapping Machine

M3-M16 CE Servo Motor Electric Multiple Spindle Tapping Machine

Metal Parts Machine Drilling Tapping Faucet Valve Multiple Spindle Cnc Vertical Drilling Machine

Customized automatic Multiple spindle drilling tapping chamfering machine for sale

GT2-223 Table Type auto feed Gear adjustable automatic Tapping And Drilling Machine with Multiple Spindle

Low Price Gear Type Tapping Machine Multi Head Drilling and Tapping Machine High Powerful Gear Type Drilling and Tapping Machine

Multifunctional Small Industrial Bench Drill And Tapping Machine Vertical Drilling Machine

Z5032/1Electric Bench Driller Taladro Drill Press Borehole Tapping Drilling Machine

Drilling Machine Multi Spindle Drilling Machine Automatic For Led Street Lights Cover Housings Die Castings Parts

Taiwan Premium Automatic Multiple Spindle Drill Press Machine With 1 Year Warranty Period

High Efficiency Drilling Tapping Machine Customized Drilling Tapping Machine Multi Spindle Drilling tapping Machine

Nut tapping machine multiple spindle drilling machine and tapping machine

LCH Wholesale Professional Adjustable Tool U Type Circle Multi Spindle Head for Drilling Tapping Machine

M8 multiple thriple spindle drilling and tapping machine tapping machine electronic precision pillar bench drill press machine

Small high speed automatic metal borehole cnc tapping drilling multiple spindle head mincing machine m16-m36

Head Multi-spindle Drill Spindle Price Best Quality Wholesale High Quality Multiple Drilling Multi

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4