Introduction to Mold Plastic Luggage Manufacturing

The realm of mold plastic luggage encompasses a diverse range of products tailored for various applications, primarily in the travel and transport sectors. This category includes the production and design of durable luggage items using precision molding techniques. Injection molding is a prevalent method, suitable for creating both intricate, functional items and larger components, such as decorative elements for various applications.

Types and Applications of Molded Luggage

Molded luggage can be categorized by size, design complexity, and material. From small, compact carry-ons to larger, check-in suitcases, the applications are extensive. Specialized luggage types, such as business cases or rugged outdoor travel gear, also fall within this category. The versatility of injection molding allows for the creation of custom luggage solutions to meet specific industry needs or consumer preferences.

Features and Materials

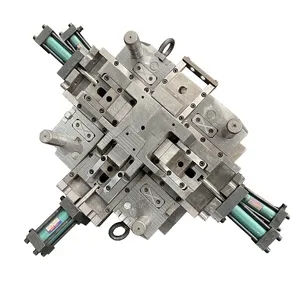

The features of mold plastic luggage are determined by the materials used and the design specifications. Common materials include various plastics and polymers, each selected for its durability, weight, and resistance to environmental factors. Iron and aluminum molds are often employed for their longevity and ability to produce fine details. The choice of material impacts the luggage's weight, texture, and overall durability.

Advantages of Mold Plastic Luggage

The advantages of using molded luggage are numerous. These items are typically lightweight, robust, and capable of withstanding significant wear and tear, which is essential for frequent travelers. The molding process allows for the integration of additional features such as reinforced corners, customizable compartments, and ergonomic handles, enhancing the functionality and user experience.

Customization and Production Efficiency

Customization is a key aspect of mold plastic luggage production. The process begins with a detailed design phase, where the dimensions and features are tailored to specific requirements. Efficiency in production can be achieved by standardizing certain mold elements, such as lift bars and clamp slots, which can be beneficial for manufacturers producing a range of luggage sizes and styles.

Selecting the Right Mold Plastic Luggage

Choosing the right mold plastic luggage involves considering the design, material, and intended use. Suppliers on Alibaba.com offer a wealth of information to assist buyers in making informed decisions. It is crucial to engage with suppliers who are committed to refining the mold until the final product meets the buyer's expectations, which may include producing test samples for quality assurance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4