Understanding Modular Cleanrooms

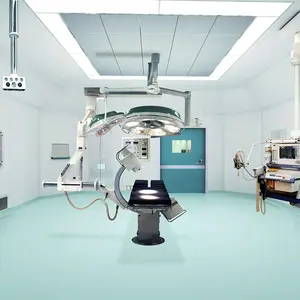

Modular cleanrooms are specialized environments designed to maintain low levels of pollutants such as dust, airborne microbes, and aerosol particles. Utilized across various industries, these structures are essential in areas where a clean atmosphere is critical for product manufacturing or research development.

Types and Applications

There are several types of modular cleanrooms, each serving distinct purposes. Softwall cleanrooms offer flexibility and are often used in electronics or pharmaceuticals, while hardwall cleanrooms provide a more permanent solution. Another type, the ballroom cleanroom, is expansive and used for semiconductor manufacturing due to its extensive space requirements. These controlled environments are pivotal in sectors like biotechnology, medical device production, and scientific research.

Features and Materials

The construction of a modular cleanroom involves materials that ensure durability and compliance with cleanliness standards. Stainless steel is commonly used for its non-porous nature and resistance to corrosion. Aluminum is another popular choice due to its lightweight and robustness. The cleanrooms' features include HEPA filters that trap 99.97% of particles, as well as specialized HVAC systems to control temperature and humidity, ensuring a stable environment.

Advantages of Modular Design

The modular aspect of these cleanrooms provides several advantages. They are scalable, allowing for expansion as business needs grow. Their prefabricated nature ensures a quicker setup compared to traditional construction, and they offer the flexibility to be dismantled and relocated if necessary. This adaptability makes modular cleanrooms a cost-effective solution for businesses looking to maintain controlled environments.

Safety and Compliance

Safety is paramount in the design of modular cleanrooms. They are engineered to adhere to stringent safety regulations, which include the incorporation of features like fire-resistant materials and spill containment systems. Compliance with these regulations is critical to ensure the safety of personnel and the integrity of the work conducted within these clean environments.

Choosing the Right Modular Cleanroom

Selecting the appropriate modular cleanroom requires careful consideration of specific needs, such as the level of cleanliness required and the amount of space available. It is essential to consult with experienced suppliers who can provide insights into the most suitable configurations and features for your particular application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4