What is Precision Metal Stamping Mold

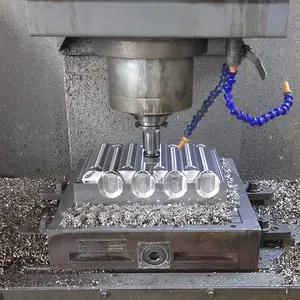

Precision metal stamping molds are specialized tools used in the manufacturing industry for shaping metal sheets into various intricate parts and components. These molds are designed to produce high-precision metal parts by leveraging the force exerted by a press machine. They are crucial for industries that require the mass production of metal components with consistent quality and high complexity, such as automotive, aerospace, and electronics.

The principle behind precision metal stamping molds is to create a form or profile that is desired, which is then repeatedly and accurately replicated on metal sheets. These molds consist of cavities and passages that define the shape of the final product. When a sheet metal is placed on the mold and the press is activated, the metal is stamped with the die's pattern, which bends and forms the material to the shape of the cavity. This process can be used for both single-stage and progressive stamping, allowing manufacturers to choose the appropriate method based on their production needs.

Precision metal stamping molds are tailored to the specific requirements of the parts they will produce. They are designed with the utmost attention to detail to ensure that the dimensions, angles, and surface finishes of the stamped metal meet the exact specifications of the end product. This level of precision is achieved through a combination of factors such as material selection, mold design, and the use of specialized techniques like EDM (electrical discharge machining) for tight tolerances.

Manufacturers who rely on precision metal stamping molds benefit from cost savings due to reduced material waste and labor costs associated with traditional machining methods. Additionally, these molds can significantly increase production speed without compromising on the quality or consistency of the parts being produced.

Types of Precision Metal Stamping Mold

Precision metal stamping molds come in various types to accommodate the needs of different projects and materials. Some of the common types include:

-

Single-Step Stamping Mold: These molds can create a part with complex shapes in one step. They are typically used for simpler parts where the material is relatively thin and uniform. This type is cost-effective and time-saving for high-volume production runs.

-

Progressive Die Stamping Mold: A progressive die stamping mold has a sequence of two or more cuts made by a single die. This type allows manufacturers to perform multiple cutting operations at once, which is ideal for intricate parts with multiple features. Automotive and electrical components often utilize progressive die stamping.

-

Compound Die Stamping Mold: Compound die molds are a variation that includes a die within a die. This allows for the creation of more complex shapes with one pass through the press. They are frequently chosen for producing parts with detailed geometries like gears and brackets.

-

Deep Drawn Stamping Mold: In deep drawn stamping, flat sheets of metal are turned into three-dimensional shapes by forming a deep-drawn cup. These are typically used for creating parts with significant depth such as beverage cans and battery cases.

Each type has its own set of common use cases based on the properties of the materials involved and the shapes required for the final products.

How to choose Precision Metal Stamping Mold

Choosing the right precision metal stamping mold requires careful consideration of several factors. The choice should align with the specific needs of the business and its customers while ensuring compatibility with the intended application.

Material selection is paramount; it impacts the durability, quality, and cost of the final stamped product. For instance, stainless steel molds offer high resistance to heat and corrosion which may be necessary for certain industries like automotive or aerospace. Hardened metals can provide added strength suitable for high-volume production runs.

The complexity of the design will also affect mold choice. More intricate designs may necessitate custom molds requiring advanced machining techniques. Additionally, considerations such as whether micro machining is required will influence the type of mold chosen.

It is also important to factor in surface finish requirements. If a product will require additional treatments like powder coating or painting, selecting a mold that accommodates these needs—such as a polished mold surface—will be essential.

Lastly, businesses should consider the type of components they plan to produce. The shape, size, and intricacy of the part will determine the type of mold that can be utilized effectively.

About Precision Metal Stamping Mold on Alibaba.com

Alibaba.com stands as a global marketplace connecting businesses with a vast selection of industrial suppliers offering precision metal stamping molds among other services. With its inception dating back to 1999 and covering over 190 countries worldwide since then, Alibaba.com has become an essential platform for small and medium-sized enterprises seeking to expand their reach and procure high-quality manufacturing tools.

The site boasts an extensive array of precision metal stamping molds suitable for various applications—from automotive parts to industrial gears—allowing businesses to find exactly what they need. Alibaba.com simplifies the international trade process by offering features such as mobile accessibility, local language communication support, order handling, delivery services, and Trade Assurance—a service that protects payments until delivery completion.

Given Alibaba.com's commitment to facilitating easy business anywhere, it's no surprise that it has become a go-to platform for many companies looking to source precision metal stamping molds efficiently. Whether you're starting out or scaling up your operations, Alibaba.com provides access to a diverse range of suppliers who can meet your business's unique requirements while upholding high standards of quality and reliability.

Common FAQs for Precision Metal Stamping Mold

What are the primary differences between precision metal stamping and regular metal stamping molds?

Precision metal stamping involves the production of complex parts with high accuracy, while regular metal stamping is typically used for simpler shapes and larger production volumes. The level of intricacy and accuracy required determines the type of mold needed.

How does material selection impact the quality of a precision metal stamping mold?

Selecting the right material for a precision metal stamping mold is crucial as it must withstand repeated cycles of stamping without deforming. The material choice also affects the mold's thermal conductivity and corrosion resistance, which are important for maintaining mold integrity and product quality.

Can precision metal stamping molds be customized to specific designs?

Yes, precision metal stamping molds can be customized to fit the unique requirements of your product, ensuring a perfect fit and optimal performance. Customization may include altering dimensions, incorporating company logos, or designing specific shapes and patterns.

What industries commonly use precision metal stamping molds?

Precision metal stamping molds are commonly used in industries such as automotive manufacturing, aerospace, electronics, medical equipment production, and machinery repair shops.

Are there any industry standards for precision metal stamping molds that businesses should be aware of?

While there may not be universal standards for all types of metal stamping molds, certain industries might have specific requirements or regulations that molds must meet. It's important for businesses to be aware of and comply with these standards.

What surface treatment options are available for precision metal stamping molds?

Surface treatment options for precision metal stamping molds include polishing, plating (chrome, zinc, nickel), painting, and powder coating. These treatments can provide additional protection against corrosion and wear.

How does the choice of core material in a precision metal stamping mold affect its performance?

The core material in a precision metal stamping mold, usually made of materials like steel or aluminum, can significantly affect the mold's durability, precision, and the quality of the stamped parts. It's important to choose a core material that can withstand repeated use and maintain its shape over time.

What considerations should be made for maintenance and repair of precision metal stamping molds?

When considering maintenance and repair needs, it's important to have access to spare parts and qualified technicians who can diagnose issues accurately. The mold itself must also be periodically inspected for wear or damage to ensure it performs optimally.

How do I ensure a long lifespan for my precision metal stamping mold?

Regular maintenance such as cleaning, lubricating moving parts, and checking for wear patterns can help ensure a long lifespan for your precision metal stamping mold. Additionally, operating within recommended temperature and pressure limits and avoiding overloading the mold can help preserve its integrity.

Can I use the same precision metal stamping mold for different types of metal alloys?

Using the same mold for different metal alloys can be possible if the mold is designed to accommodate various material compositions. However, it's crucial to verify that the mold's specifications align with the specific alloy requirements to ensure optimal performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4