Metal cutting tools are instruments explicitly designed for the precise and efficient cutting of metal materials. The tools are crucial in various industries, including construction, manufacturing, and metalworking.

Vital Features of Metal Cutting Tools

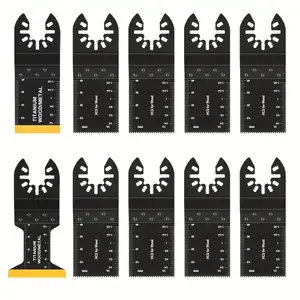

Metal cutters exhibit several vital features. One prominent feature is the cutting edge, often made from hard materials like high-speed steel or carbide. This sharp cutting edge ensures the tools can effectively slice through metal accurately. Additionally, many metal cutting blades incorporate multiple flutes or teeth along the cutting edge, enhancing the tool's cutting ability and allowing for the removal of metal chips during the process. They come in various types, including drills, end mills, lathe tools, and saw blades, each tailored for specific metal-cutting tasks. Whether used in industrial settings or by hobbyists, the sheet metal cutters are engineered to provide precise and accurate cuts, contributing to the overall quality of the finished product.

Durability of Metal Cutting Tools

Durability is a crucial aspect of the metal cutter. The tools are often crafted from robust materials, such as high-speed steel, carbide, or cobalt, which can withstand the intense forces and heat generated during metal cutting. The durability of the materials contributes to the tool's longevity and reduces the need for frequent replacements. Advanced technologies, such as computer numerical control (CNC) machining, further enhance the precision of metal-cutting processes. Many sheet metal cutting tools also incorporate coatings or treatments to improve performance. Titanium nitride (TiN) or other coatings may be applied to reduce friction, enhance hardness, and increase resistance to wear. The coatings contribute to smoother cutting operations and extend the tool's lifespan.

Tool Variety and Applications of Metal Cutting Tools

One common type is the hacksaw, a handheld tool featuring a fine-toothed blade tensioned in a frame. Hacksaws are versatile and suitable for cutting through metal pipes, rods, and other small components. The angle grinder is another widely used metal cutting machine, which employs a rotating abrasive disc to cut through metal. Additionally, power shears are electric or pneumatic tools designed for cutting through sheet metal. They offer a quick and efficient way to produce straight or curved cuts with minimal effort. Metal nibblers are employed for more precision in intricate metalwork. Nibbler metal cutters feature a punch-and-die mechanism to create precise cuts without distortion. Plasma cutters utilize a high-temperature, ionized gas to melt and cut through metal, providing a fast and accurate method often used in industrial settings. Laser cutters, a more advanced technology, use a focused laser beam to melt or vaporize metal, allowing for precise cuts in various shapes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4