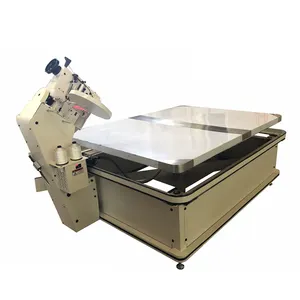

Introduction to Mattress Tape Edge Sewing Machines

The mattress tape edge sewing machine is an essential piece of equipment in the mattress production industry. This specialized machine is designed to streamline the process of attaching the tape edge to mattresses, ensuring a neat finish and enhancing the overall quality of the final product. The category encompasses a variety of machines, each tailored to different aspects of the tape edging process.

Types and Applications

From the automatic mattress tape edge machine to more manual options, these machines serve the purpose of edging a wide range of mattress types. The automatic variants are particularly beneficial for larger operations where efficiency and consistency are key. Each type of machine is suited for specific applications, whether it's for standard mattress sizes or custom orders, providing the flexibility to meet diverse production demands.

Features and Materials

A typical tape edge sewing machine is equipped with features that can handle various materials and thicknesses, accommodating the diverse fabrics used in mattress manufacturing. The machines are constructed from durable materials, ensuring longevity and reliability in a high-volume production environment. Advanced models include touch screen controls and programmable stitch sequences, which allow for precise and customizable edging.

Advantages of Upgraded Machines

Upgrading to an automatic tape edge machine can significantly enhance production efficiency. These machines reduce manual labor and help maintain a consistent quality in the tape edging process. The integration of electronic components in modern machines also allows for greater control over the sewing operation, resulting in a superior finish.

Cost-Effectiveness and Efficiency

While the mattress tape edge machine price is a consideration for any business, the investment in the right machine can lead to increased cost-effectiveness in the long run. The efficiency of an automated process can lead to a reduction in production time and labor costs, making it a valuable asset for mattress manufacturers.

Choosing the Right Machine

Selecting the appropriate machine, such as a model with a competitive tape edge machine head price, is crucial for businesses looking to optimize their production line. Factors to consider include the machine's compatibility with existing production processes, the types of mattresses to be edged, and the volume of production required.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4