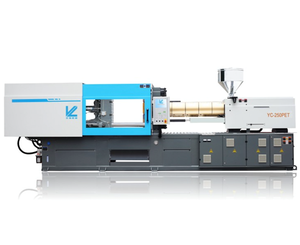

Introduction to LSR Injection Molding Machines

Liquid silicone rubber (LSR) injection molding machines are at the forefront of manufacturing technology, providing a streamlined solution for producing items with precision and efficiency. These machines are engineered to cater to a broad spectrum of industries, ranging from consumer electronics to the automotive sector. The core advantage of an LSR injection molding machine lies in its ability to deliver products with consistent quality and intricate detail.

Types and Applications

The versatility of LSR molding equipment is evident in its various types, each tailored for specific applications. Whether it's creating thin-walled containers for the packaging industry or complex PVC pipe fittings, these machines are designed to meet diverse manufacturing needs. The adaptability of silicone injection molding machines extends to their use in the pharmaceutical and food & beverage industries, where precision and hygiene are paramount.

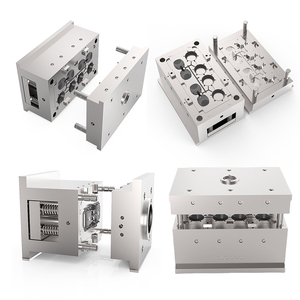

Features and Materials

An LSR molding machine is characterized by its robust construction and the use of durable materials, ensuring a long service life. The integration of a single-cylinder system with a servo-valve ensures responsive operation, while the specialized screw design enhances plasticizing capabilities. The steel bush in the clamping unit is innovatively structured to minimize wear resistance, which contributes to the longevity and reliability of the machine.

Advantages of LSR Molding Technology

Investing in an LSR injection molder translates to several benefits, including improved accuracy and reduced waste, which are crucial in high-end applications. The clamping force of these machines is adept at resisting external machining forces, ensuring the production of components with precise dimensions. Additionally, the new structure of the steel bush reduces the need for lubrication, potentially lowering operational costs.

Capacity and Precision

The clamping force of an LSR injection molding machine can range significantly, accommodating various production scales. This force is a critical factor in the machine's ability to maintain dimensional stability under the pressures of injection molding. The precise control over the molding process ensures that each product meets the stringent standards expected in today's competitive markets.

Choosing the Right Machine

Selecting the appropriate liquid silicone rubber injection molding machine is pivotal for any plastic processing business. Prospective buyers should consider the specific requirements of their applications, such as the size of preforms and the desired shot weight and speed. The machines available through Alibaba's platform are designed to shape plastic granules into the required dimensions with enhanced accuracy, making them a valuable asset for manufacturers aiming to optimize their production processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4