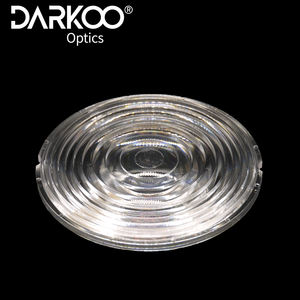

A large Fresnel lens is a type of composite compact lens that is much thinner and lighter than conventional lenses. It comprises a series of concentric grooves, which allows it to be more lightweight and have a reduced thickness compared to traditional lenses. The largest Fresnel lenses, known as hyperradiant or hyper-radial, can be several meters tall and are used in applications such as lighthouses and solar energy concentration. These lenses are used to concentrate light. They have various applications, including in lighthouses, solar energy, photography, and retina identification cameras. Notably, there are different types of Fresnel lenses, each suited to different types of applications. The two main types of Fresnel lenses are imaging and non-imaging lenses. Imaging Fresnel lenses use segments with curved cross-sections and produce sharp images, while non-imaging lenses have segments with flat cross-sections and do not produce sharp images. As the number of segments increases, the two types of lenses become more similar to each other.

Fresnel lenses are often used in light-gathering applications, such as condenser systems or emitter/detector setups. They can also be used as magnifiers or projection lenses in illumination systems and image formulation. Besides, some 3D glasses use Fresnel lenses to make the lenses thinner and lighter, providing a more comfortable viewing experience.

Common materials used to make fresnel lenses

Fresnel lenses can be made from various materials, including glass and different types of plastics. Glass Fresnel lenses can be fabricated with computer-controlled milling. They are usually made as a single piece of material. On the other hand, large plastic Fresnel lenses are often made from materials such as acrylic, polycarbonate, cyclic olefin copolymers (COC), and other specialized polymers. These materials transmit light in the visible, near-infrared, and ultraviolet spectra. Modern manufacturing techniques, such as compression injection molding and computer-controlled machining, have made it possible to produce high-quality polymer Fresnel lenses that outperform traditional glass lenses in some applications. Plastic Fresnel lenses are also larger, cheaper, and lighter than glass lenses, making them suitable for various applications, including solar energy concentration and light collimation.

Fresnel lenses' effect on the quality of light

Fresnel lenses affect the quality of light in several ways. They efficiently focus light output, producing a sharp yet soft beam, and offer adjustable focus, allowing a seamless transition from spotlight to floodlight. The Fresnel lens captures and focuses more light than a traditional lens, which means that less energy is needed to produce the same level of illumination, making them ideal for use in situations where power consumption is a concern. Additionally, a large spot Fresnel lens can produce a hard-edged beam of light, making it suitable for creating dramatic shadows and highlights and accentuating textures and details in a scene.

How to adjust the beam width of a fresnel lens spotlight

To adjust the beam width of an extra large fresnel lens, the user can move the lamp and reflector closer to or farther away from the lens. Moving the lamp closer to the lens makes the field wider, creating a floodlight effect, while moving the lamp away from the lens makes the field smaller, producing a spotlight effect. This adjustable focus allows a seamless transition from spotlight to floodlight, making Fresnel lenses versatile for various lighting setups.

Alibaba.com has a wide variety of large Fresnel lens for sale. Check them out to buy in bulk at affordable prices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4