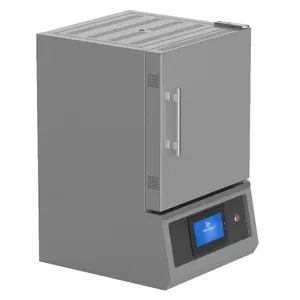

Discover the Versatility of Kejia Furnaces

Industrial furnaces are pivotal in metallurgical processes, and kejia furnaces stand out for their efficiency and adaptability. These robust machines are primarily utilized for melting a variety of metals, including iron, aluminum, and copper, as well as precious metals like gold, silver, and platinum. The versatility of a kejia melting furnace is evident in its ability to handle different materials, making it a valuable asset in industrial settings.

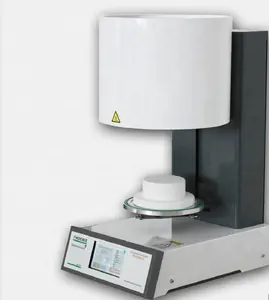

Technical Specifications and Features

The technical prowess of industrial melting furnaces is showcased in their substantial weight capacity, reaching up to 20 tons, and their power input range from 380v to 950v. With working power spanning from 180kw to 2,000kw, these furnaces are designed to meet diverse metallurgical needs. The integration of large capacitor banks ensures a stable current flow to the electric arc furnace, enhancing the safety and efficiency of the melting process. Additionally, safety systems, including circuit breakers, are in place to mitigate any operational faults, ensuring a secure working environment.

Operational Excellence

Melting methods in a kejia furnace can be either open or enclosed, with certain models requiring dual pots for both melting and transportation of molten metal. The temperature control within these furnaces is precise, typically ranging from 2,100 to 1,750 degrees Celsius, which is sufficient for melting most metals. The melting speed is also optimized, with durations ranging from 40 to 60 minutes based on the metal type and furnace model. The tilting capability of melting pots, reaching up to 95 degrees, allows for complete evacuation of molten metal, demonstrating the user-centric design of these furnaces.

Advanced Cooling and Control Systems

Each kejia industrial furnace is equipped with a water-cooling system to manage the high temperatures involved in metal processing. The operational aspects are further enhanced by a PLC system, which provides a sophisticated yet user-friendly interface to control the furnace. The use of electrical induction systems for heating and hydraulic pressure systems for tilting are testaments to the advanced technology employed in kejia furnaces.

Choosing the Right Kejia Furnace

Selecting the appropriate kejia melting furnace is crucial for meeting specific industrial requirements. While the size and capacity of the furnace are important considerations, the type of metal to be melted and the desired melting speed also play significant roles in the selection process. Prospective buyers can explore a range of kejia furnaces on Alibaba.com, each designed to cater to different operational scales and metallurgical needs.

Conclusion

For businesses in search of reliable and efficient melting solutions, kejia furnaces offer a range of industrial furnaces to suit various metal processing demands. Without making any specific promises on behalf of Alibaba.com, it is clear that the platform provides a diverse array of options to consider. Interested parties are encouraged to peruse the selection available on Alibaba.com to find a furnace that aligns with their industrial requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4