Jelly Bean Making Machines: An Overview

Jelly beans, a staple in confectionery delights, are produced with precision and efficiency thanks to jelly bean making machines. These machines are the cornerstone of production for businesses looking to cater to the sweet tooth of a diverse clientele. With a range of capabilities, from small-scale manual operations to large-scale automated systems, these machines are designed to meet various production needs.

Types and Applications of Jelly Bean Machinery

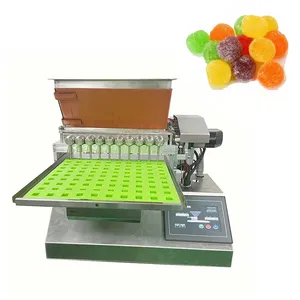

The confectionery industry utilizes different types of machinery for jelly bean production. Manual liquid fillers are ideal for entrepreneurs starting with smaller operations. They operate without electricity, enhancing production speed and precision over hand-filling methods. For larger scale production, semi-automatic and fully-automatic jelly bean making machines are more appropriate, streamlining the manufacturing process and increasing output.

Features and Materials

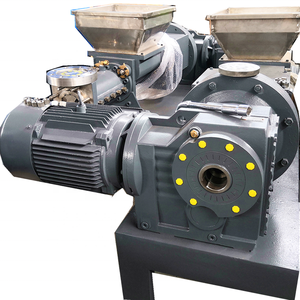

Modern jelly bean machines are constructed with materials that ensure durability and compliance with food safety standards. Stainless steel is commonly used for its resistance to corrosion and ease of cleaning. These machines come equipped with features such as vibratory weigh fillers for precise ingredient measurements and positive displacement pump fillers, which are particularly useful for handling high-viscosity substances like gels or pastes.

Advantages of Automated Jelly Bean Production

Automated jelly bean equipment offers a multitude of advantages. The ability to operate 24/7 allows for a consistent production flow, essential for meeting market demands. Additionally, the versatility in stocking various types of confectionery items means businesses can adapt to sales trends and consumer preferences with ease.

Complementary Equipment for Jelly Bean Making

Beyond the core machinery, complementary equipment can enhance the jelly bean production line. For instance, a jelly belly cotton candy making kit can diversify a confectionery business's offerings. Capsule fillers, while traditionally used in pharmaceuticals, can also be adapted for candy making, providing additional versatility to the production process.

Choosing the Right Jelly Bean Machine

Selecting the appropriate jelly bean making machines involves considering production volume, space, and the specific types of confectionery products to be made. Whether it's integrating a jelly belly cotton candy making kit into an existing line or starting fresh with a new jelly bean machine, the right equipment is out there to meet every business's needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4