Introduction to Japanese Bending Machines

The realm of metalworking and construction demands precision and efficiency, where the Japanese bending machine plays a pivotal role. This category encompasses robust equipment designed for the manipulation of metal, primarily to achieve precise bends and shapes. The utilization of a bending machine from Japan is integral in industries that require the shaping of metal sheets and bars, including but not limited to automotive, housing, and aerospace sectors.

Types and Applications

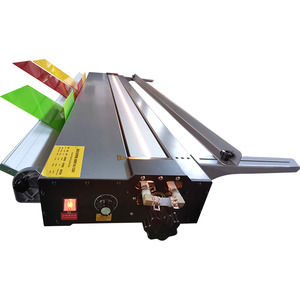

There are various types of Japanese bending machines, each serving a specific purpose. From compact units suitable for small workshops to industrial-grade machines for heavy-duty use, the spectrum is broad. These machines are adept at handling a range of materials and thicknesses, making them versatile for producing components in diverse industries. The application of these machines extends to creating intricate parts for machinery, framing structures for buildings, and components for vehicles.

Features and Materials

A bending machine Japan-made is recognized for its innovative features that cater to efficient metal shaping. The machines are engineered to handle various metals, from steel rebar to delicate metal sheets, without compromising on the precision of the bend. The construction of these machines often involves robust materials that withstand the stress of bending operations, ensuring longevity and consistent performance.

Advantages of Utilizing Japanese Bending Equipment

The primary advantage of employing a Japanese bending machine lies in its speed, which significantly elevates production rates. By bringing metal bending in-house, businesses can reduce outsourcing costs and enhance quality control. Furthermore, these machines contribute to material conservation by minimizing waste during the bending process. Another notable benefit is their ability to perform hemming, which is the folding of metal edges to ensure safety by eliminating sharpness.

Operational Versatility

Versatility is a hallmark of the Japanese bending machine, with its capacity to adapt to various bending tasks. This flexibility allows for a wide range of shapes and sizes to be achieved, catering to custom and standard manufacturing needs. The operational range of these machines makes them a valuable asset in settings that require a quick turnaround of diverse metalwork projects.

Conclusion

In conclusion, a Japanese bending machine is an indispensable tool for businesses looking to enhance their metalworking capabilities. Its speed, versatility, and precision offer a competitive edge in various industrial applications. While Alibaba.com serves as a platform connecting buyers with a multitude of suppliers, it is essential to conduct thorough research to find a machine that aligns with specific business needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4