Introduction to Japan Shearing Machines

Shearing machines from Japan are integral to metal fabrication, offering precision and reliability. These machines come in various forms, including mechanical, hydraulic, swing beam, and guillotine types, each designed to meet specific industrial needs. Understanding the capabilities and applications of a japan shearing machine is crucial for businesses looking to enhance their metalworking operations.

Types and Applications

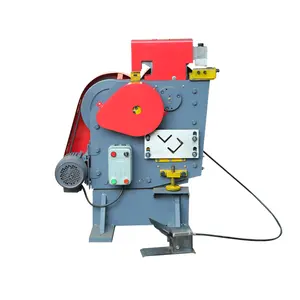

The diversity of japan shearing machines encompasses models suitable for different metals and thicknesses. Mechanical shears are often preferred for their robustness, while hydraulic models provide controlled force distribution. Swing beam shears offer simplicity and ease of use, whereas guillotine shears are known for their precision. The application of these machines spans across various industries, from automotive to construction, where they are used to cut sheet metal with accuracy and speed.

Features and Materials

A japan shearing machine is typically characterized by its sharp blades, durable construction, and advanced control systems. These machines are engineered to handle a range of materials, from light gauge metals to thicker alloys, ensuring clean cuts and consistent performance. The choice of material for the machine components is critical, often involving hardened steel or composites for longevity and resistance to wear.

Advantages of Japanese Shearing Technology

The advantages of using a japan shearing machine are manifold. Precision engineering ensures uniform cuts, while the design often incorporates features that reduce material wastage. The efficiency of these machines is reflected in their ability to maintain continuous operation, thereby enhancing productivity. Additionally, the ergonomic design of Japanese shearing equipment often emphasizes user safety and ease of maintenance.

Selecting the Right Shearing Machine

Choosing the right japan shearing machine involves considering the nature and thickness of the materials to be cut. For light gauge metals, an electrically powered shear may be sufficient, while thicker materials might necessitate a mechanical model with shock-absorbing features. The workspace size is also a determining factor, as the machine should fit efficiently within the designated area. Furthermore, operational efficiency should be a priority, with a focus on machines that can sustain long operational hours to maximize throughput.

Finding Your Shearing Machine on Alibaba.com

For businesses in search of a japan shearing machine, Alibaba.com offers a comprehensive platform to connect with suppliers. The site's search and filter tools allow for a streamlined process to locate the machinery that aligns with your specific requirements. With a vast array of options available, Alibaba.com facilitates the procurement of shearing machines that embody the innovation and craftsmanship of Japanese manufacturing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4