Introduction to IV Sets Injection Machines

Injection molding technology has revolutionized the production of intravenous (IV) set components, and the IV sets injection machine stands at the forefront of this innovation. These machines are engineered for precision and durability, catering to the demanding needs of the medical industry. The IV sets injection machine is a pivotal asset for manufacturers looking to produce high-quality medical components efficiently.

Types and Applications

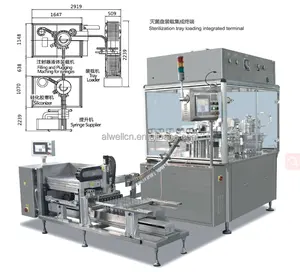

The versatility of plastic injection molding equipment extends to various applications, from medical devices to packaging. Specifically, IV sets injection machines are adept at creating components for medical use, such as drip chambers, needle hubs, and other intricate parts of an IV set. These machines are not limited to the medical field but also serve industries requiring precision plastic parts, including consumer electronics and automotive sectors.

Features and Materials

An IV sets injection molder is characterized by its robust construction and the use of high-grade materials that ensure a long service life. The machinery typically incorporates a special screw design that enhances plasticizing capabilities, ensuring consistent shot weights and speeds. The clamping force of these machines varies, providing the necessary resistance against external forces during the molding process.

Advantages of Modern Molding Machines

Investing in a state-of-the-art plastic injection moulding machine brings several advantages. The precision of these machines translates into reduced defective rates and improved accuracy in final products. Additionally, the single-cylinder system with a servo-valve ensures a responsive operation. The design of the steel bush in the clamping unit is optimized to minimize wear resistance, which can lead to savings in maintenance costs, particularly in lubrication.

Capacity and Durability

The plastic injection molding machine boasts a clamping force that can handle a wide range of external machining forces, making it suitable for producing durable products like thin-wall containers and PVC pipe fittings. The durability of these machines is a testament to their design, which focuses on long-lasting service without compromising the precision required for medical-grade components.

Choosing the Right Machine

Selecting the right IV sets injection machine involves understanding the specific requirements of your production line. Machines on Alibaba.com are designed to accommodate different sizes of preforms and are equipped with features that cater to a variety of plastic processing needs. By browsing the extensive listings, buyers can find machines that align with their operational demands and production goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4