What are Iron Wire Mesh

Iron wire mesh is a versatile and widely used material in various applications across the industrial, construction, agricultural, and home sectors. It consists of intersecting lines of iron wire welded or woven together to form a grid-like structure that can have various shapes and sizes of openings. The strength, durability, and flexibility of iron wire mesh make it an ideal choice for tasks ranging from reinforcing concrete in building construction to serving as fencing in agricultural settings.

The primary function of iron wire mesh is to provide a barrier or to reinforce other materials. In construction, for example, it is used to add tensile strength to concrete slabs, preventing cracking and structural failure. In agricultural applications, iron wire mesh can serve as fencing to protect livestock or as chicken cages. The design principles behind wire mesh focus on achieving the right balance between the diameter of the wire and the size of the openings (or apertures), ensuring that it can withstand the forces it is subjected to while fulfilling its intended function.

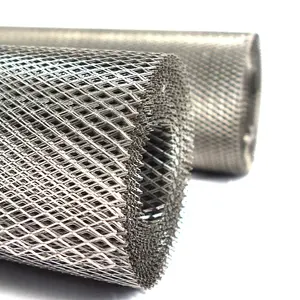

Iron wire mesh can be manufactured through different processes including welding and weaving. Welded wire mesh has wires that are welded at the intersections to provide a uniform and stable grid, whereas woven wire mesh involves the interlocking of wires through various weave patterns. Each method gives the final product distinct properties in terms of strength, flexibility, and suitability for certain applications.

This product caters to businesses involved in construction, manufacturing, landscaping, agriculture, and many other industries that require strong and durable mesh products. The effectiveness of iron wire mesh lies in its simplicity – the structure provides security or reinforcement while allowing for visibility and ventilation. This combination of functionality and practicality is what makes iron wire mesh an indispensable component in many commercial projects.

Types of Iron Wire Mesh

Iron wire mesh comes in a variety of forms, each designed to meet specific requirements and use cases:

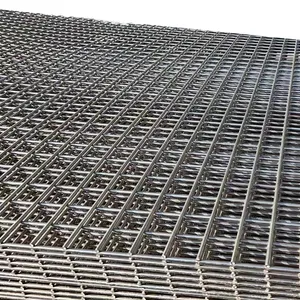

Welded Wire Mesh: This type features iron wires welded at every intersection creating a solid construction. Due to its rigidity and durability, welded wire mesh is frequently used in building construction areas for reinforcement purposes as well as for garden fences and sports fences where strong barriers are needed.

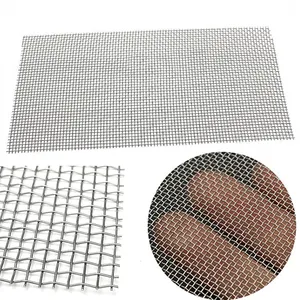

Woven Wire Mesh: With wires woven over and under each other at right angles, this type allows for more flexibility compared to welded mesh. It is commonly used as filter media in industrial applications or as protective mesh in various settings due to its ability to conform to different shapes.

Galvanized Wire Mesh: To prevent rusting, iron wires are coated with zinc in this type of mesh. Its corrosion resistance makes it suitable for outdoor use such as highway fencing or retaining walls where exposure to environmental elements is significant.

PVC Coated Wire Mesh: Iron wire mesh with a protective layer of PVC offers both durability and aesthetics. This type is often found in decorative applications or where additional protection against weathering is necessary. Gardens and residential areas benefit from this type's visual appeal and longevity.

Hexagonal Wire Mesh: Known as chicken wire or rabbit mesh, this type has hexagonally shaped gaps and is often used in agricultural settings for making chicken cages or protecting plants in gardens from pests.

Each type offers unique benefits that cater to particular requirements such as strength needed for security barriers or specific weave patterns suitable for filtering operations.

How to choose Iron Wire Mesh

Selecting the right iron wire mesh involves considering several factors that align with your business needs:

Material Durability: Depending on whether the mesh will be exposed to harsh weather conditions or corrosive substances, options like galvanized or PVC coated iron wire meshes may be preferred for their increased resistance against rust and corrosion.

Mesh Design: The choice between welded or woven designs will be dictated by whether you need greater rigidity or flexibility. Welded meshes offer firmness ideal for structural support while woven meshes provide pliability useful for applications requiring shaping.

Aperture Size: The size of the openings should suit the intended purpose – smaller apertures are essential for finer filtration processes whereas larger ones might be more suitable for fencing where visibility is required.

Wire Diameter: A thicker wire diameter translates into stronger mesh which might be necessary for heavy-duty barriers or enclosures. Conversely, thinner wires may suffice for interior decorative applications.

Processing Services: Some projects might require custom processing services like cutting, bending, punching, or weaving which certain suppliers can provide based on your specifications.

Businesses must also take into account factors such as ease of installation, longevity under operational conditions, maintenance requirements, and cost-effectiveness when choosing the right iron wire mesh product.

Best Iron Wire Mesh on Alibaba.com

Alibaba.com stands out as a premier online marketplace for sourcing wholesale iron wire meshes suitable for a myriad of commercial uses. With an extensive selection of products from reputable suppliers around the globe, businesses can find exactly what they need – from construction-grade welded meshes to decorative PVC coated options. Not only does Alibaba.com offer a range of materials including low-carbon iron wire and stainless steel options but also different weave styles like plain weave, Dutch weave, and twill weave catering to specialized applications.

As a platform that serves businesses across over 190 countries, Alibaba.com understands the importance of reliability and trust in B2B transactions. That's why features such as Trade Assurance are offered – providing payment protection until delivery completion ensuring peace of mind when ordering large quantities or customized products. Moreover, with tools facilitating communication in local languages and services like 3D modeling and graphic carton design assistance available on Alibaba.com – buyers can navigate their purchase with ease while maximizing efficiency.

For businesses looking to fulfill their iron wire mesh needs with confidence, Alibaba.com provides a streamlined solution that amalgamates vast product variety with secure trading experiences. Whether it's reinforcing structures in construction projects or crafting garden fences with aesthetic appeal, Alibaba.com's offerings stand ready to meet commercial demands with professionalism and precision.

Common FAQs for Iron Wire Mesh

What is the main use of iron wire mesh in construction?

Iron wire mesh is predominantly used in construction to reinforce concrete, preventing cracking and providing tensile strength to structures such as foundations, walls, and slabs.

How does the choice of material affect the durability of iron wire mesh?

The durability of iron wire mesh can be significantly affected by the choice of material. Galvanized or PVC coated meshes offer enhanced resistance to environmental factors like moisture and chemicals, which may otherwise lead to corrosion and rust.

Can iron wire mesh be customized to fit specific project requirements?

Yes, many suppliers offer processing services such as cutting, bending, punching, and weaving to tailor iron wire mesh to meet the unique specifications of different projects.

What factors should be considered when selecting the aperture size of iron wire mesh?

When selecting aperture size, consider the intended use – smaller apertures are suitable for filtration needs while larger openings may be better for enclosures or barriers where visibility is important.

What is the significance of wire diameter in the selection of iron wire mesh?

Wire diameter impacts the strength and rigidity of the mesh. A thicker wire diameter is essential for high-security barriers or heavy loads, whereas thinner wires are adequate for decorative purposes or lower stress applications.

How does woven wire mesh differ from welded wire mesh?

Woven wire mesh offers flexibility and is capable of conforming to various shapes, making it suitable for filtering and protective applications. Welded wire mesh provides a more rigid structure, ideal for reinforcement and heavy-duty barriers.

What are some common applications for PVC coated iron wire mesh?

PVC coated iron wire mesh is often used for aesthetic purposes in residential and garden settings due to its appealing appearance and enhanced durability against weathering.

Is galvanized iron wire mesh suitable for outdoor applications?

Galvanized iron wire mesh is very suitable for outdoor applications as the zinc coating provides added protection against rust and corrosion caused by exposure to the elements.

How do I know if I need a plain weave, Dutch weave, or twill weave iron wire mesh?

The weave style selection depends on your specific application; plain weave is standard and versatile, Dutch weave offers finer filtration, and twill weave provides a tighter structure suitable for high-pressure filtration processes.

Can iron wire mesh be used as a security barrier?

Yes, with a proper selection of thickness, aperture size, and material treatment like galvanization or PVC coating, iron wire mesh can effectively serve as a security barrier.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4