Understanding Interlining Fusing

Interlining fusing is a critical component in the textile and garment manufacturing industry, serving as a stabilizer and structure-provider for various apparel items. This category encompasses a broad range of materials designed to be fused to fabric to enhance its properties and performance. Interlining fusing plays a pivotal role in the structure and final appearance of garments, making it an essential selection for manufacturers.

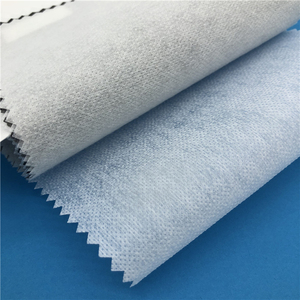

Types and Applications of Interlining Fusing

The versatility of interlining fusing is evident in its various types, such as microdot fusing and non woven fusing, each serving specific applications. For instance, shirt collar fusing interlining is specifically designed to provide crispness and shape retention to collars, a crucial aspect of men's and women's formal wear. Similarly, woven fusing interlining is often utilized in areas requiring more flexibility and softness, such as in women's blouses and men's suit jackets.

Features and Materials

Interlining fusing materials come in various compositions, including options like stretchable, shrink-resistant, and water soluble interlining fusing. The choice of material—ranging from polyester (PES) to polyamide (PA)—is dictated by the desired properties and the specific application of the end product. The color range, typically including white, black, and gray, allows for seamless integration into a multitude of fabric designs.

Advantages of Interlining Fusing

The use of interlining fusing brings numerous advantages to the garment-making process. It enhances the structural integrity, ensures better shape retention, and adds to the durability of the clothing item. Moreover, the inclusion of microdot fusible interlining offers a uniform bond and a clean finish, which is particularly beneficial in lightweight and delicate fabrics.

Selection Considerations

When selecting fusing interlining fabric, it is crucial to consider the fabric compatibility, desired hand feel, and the durability required for the garment's intended use. The choice between double-dot or single-dot applications, each providing a different level of adhesion and stability, is also a key consideration for manufacturers looking to achieve the best results for their products.

Environmental and Practical Implications

In today's environmentally conscious market, the impact of textile materials is a growing concern. Interlining fusing options that prioritize eco-friendliness without compromising on performance are increasingly in demand. Additionally, practical factors such as ease of application and maintenance are important for end-users, influencing the choice of interlining materials by manufacturers.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4